leeeboo

Member

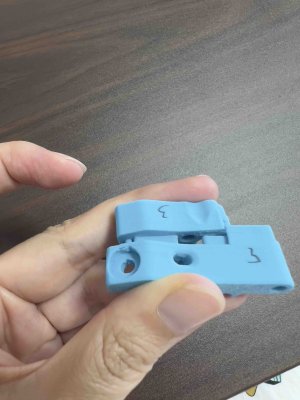

Hi guys I have a problem that confuses me. I have adjusted my printer(VORON 2.4), PA, EM, hole enlargement etc. all done, but when printing Stealthburner Clockwork2 guidler a and b, these two parts are quite difficult to assemble, it seems the discrepancy was quite large. Does anyone have any ideas what the problem was? Thank you guys so much!