I can't figure out what kind of isulation you're talking about.

Almost ANYTHING willwork. Toss a bllanket over the printer and tie it one with rope. Of course that isugly and not pratical but people have used carboard boxes and packing tape.

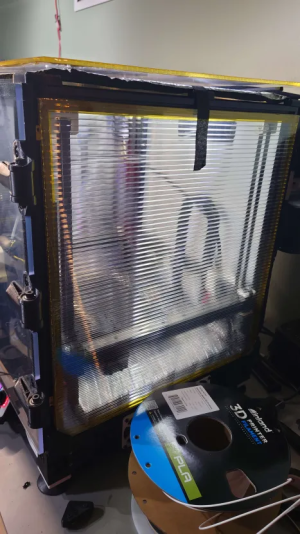

I think the best looking solution is to double glase the pannels. The stock printer uses 3mm PC sheets but you can install two sheets with a 20mm air gap but this requires a lot of work and thinking and designing brakets to hold the second sheet in place.

But more common is just to use insulation foam. It is used for building, residential and comerial. Usually it is a white or pink rigid foam with alumium foil llaminated to one side. Cut this so that it friction tifs inside the frame or make a 4-sided box that slips over the entire printer.

Friction fitting inside means the foam can be not thicker then the 2020 extrusion but and exterioir shell can be as thick as you like.

Seriously, prople have used cardboard and tape

I have found that a lot of heat passes through the top pannel. Siply folding up a bath towel and setting on top of the printer prevents some heat loss.

About the idea of usoing a "standard" Raspberry Pi "Pico" as an MCU. That works and they cost only $4 and give you ab out a dozen or so more pins (although only four analog pins). But they are just bare pins with no connectors on them, you have to add level shifters, mosfet switches and JST connectos and whatever else you need. So you might as well just buy a purpose-build Klipper MCU for BTT or one of the others. I used the custon, hand-built method for experiments on the bench because I happen to have a big stock of these parts

You could even use an old Arduino Uno as a Klipper MCU.

The easy why to know what will work is when you compile Klipper there is a menu, any processor on that menu will work

Finally, notice there is a "linux" MCU. Klipper can run a process in the host Pi3/Pi4 that accesses the GPIO pins. You can not connect a thermister directly to a Pi3 GPIO but you can connect a serial interface temperture sensor. I have five of these on my Pi3 right now, all sharing one GPIO pin. The sample rate is dead slow but I'll use these for chanmber temperature and things like the power supply heat sink and motor temperature. I'm testing reliablity on the bench now. I keep finding and fixing pron=blems and now it is running 24x7 for a couple weeks. This si the problem wwith self-build interfaces, youare going to make mistakes and are going to have to be able to find and fix them. Most people will just spend the money one a second (or thoird) camerical MCU.