Hi. I just built my first Trident, LDO Rev D. It is working, but somewhat rapid downward z motion (as when homing or z-tilt) sounds like a grumpy walrus. The cause is vibration of the rear lead screw. I can silence it by damping the vibration with a finger near the top of the lead screw. I don't know the exact physics of the vibration/chattering, but sure it is my fault. I failed to notice that LDO's recommended printer config did not did not default to the correct TR8x4, wondered why my prints were short, and when I finally realized the problem, in my excitement to try out the fix I failed to remember I had to edit each individual extruder config. So that next first homing went... badly and probably tweaked the lead screw and/or the POM nut.

The printer seemed to work well enough to print most of the remaining parts with it but it doesn't sound right and I'm wondering if the problem is affecting the z offset a bit.

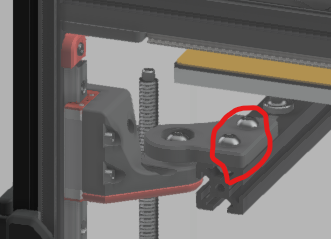

I removed and inspected the POM nut and saw a bit of thread wear. But didn't notice obvious cracking. The lead screw seems ok, but haven't pulled the motor out to lay on a surface.

Things I've thought of:

The printer seemed to work well enough to print most of the remaining parts with it but it doesn't sound right and I'm wondering if the problem is affecting the z offset a bit.

I removed and inspected the POM nut and saw a bit of thread wear. But didn't notice obvious cracking. The lead screw seems ok, but haven't pulled the motor out to lay on a surface.

Things I've thought of:

- Replace the POM nut if I can find the same one for sale, and see if that matters.

- Try to straighten the lead screw (might do more harm than good?)

- Lubricant?

- Replace the motor assembly.

- Craft a damper to lightly hold the top of the lead screw