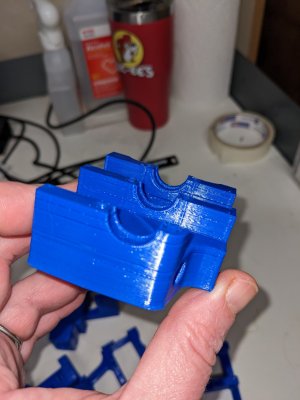

Trying to print the parts for a 2.4 R2. I must have run through a spool of ABS trying to get the quality OK, but when I print at 40% infill, I get a lot of gaps or underextruded sections. If I drop infill to 30% or 35% its better - almost resolved. I did find that Hatchbox ABS has less problems than the Esun ABS I started with.

Details:

Ender 3 v2, direct drive all metal hot end, side mounted spool with bearings on the rollers. I tuned this using Teaching Tech's procedures

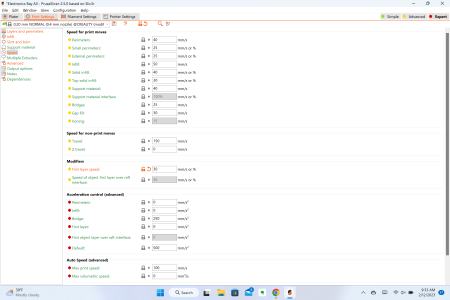

Prusa Slicer

Bed at 100, nozzle at 250

Hatchbox ABS

Using the Voron PIF print settings

Any suggestions on how to fix this? Is 30% infill strong enough?

Thanks all

Details:

Ender 3 v2, direct drive all metal hot end, side mounted spool with bearings on the rollers. I tuned this using Teaching Tech's procedures

Prusa Slicer

Bed at 100, nozzle at 250

Hatchbox ABS

Using the Voron PIF print settings

Any suggestions on how to fix this? Is 30% infill strong enough?

Thanks all