- Printer Model

- voron 2.4r2

- Extruder Type

- Clockwork 2

- Cooling Type

- Stealthburner

hi,

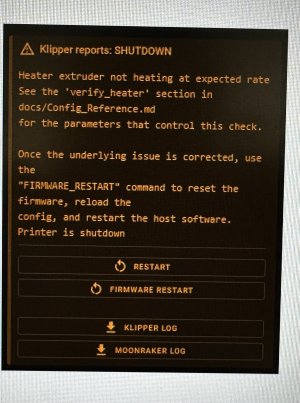

my voron 2.4r2 has been working very well for about 6 months with stealthburner. all the sudden it would stop midprint and report adc out of range. i have replaced the hotend thermistor and heater cartridge. now it will stop mid print and report verify_heater error; the led on the sb would go out when this happens…

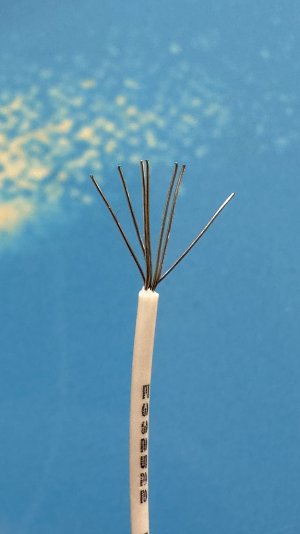

0. replaced the thermistor and 65w heater cartridge twice

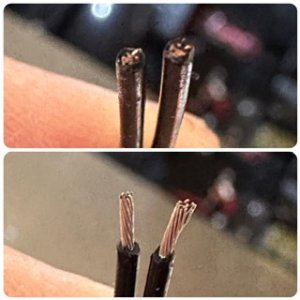

1.checked the 2 piece pcb connector and wires for continuity all the way to the main board. i even went and solder the thermistor to the pcb.

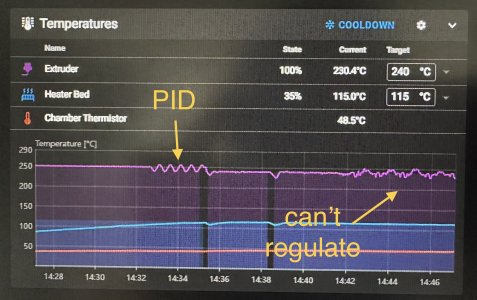

2.performed a PID with 10% fan on many times

3.i have routed both thermistor and heater to new locations on the main board, and updated the printer.cfg accordingly

it appears from the picture that it cannot regulate the hot end temperature during printing but can sit idle for a long time without issues. any advice is appreciated

my voron 2.4r2 has been working very well for about 6 months with stealthburner. all the sudden it would stop midprint and report adc out of range. i have replaced the hotend thermistor and heater cartridge. now it will stop mid print and report verify_heater error; the led on the sb would go out when this happens…

0. replaced the thermistor and 65w heater cartridge twice

1.checked the 2 piece pcb connector and wires for continuity all the way to the main board. i even went and solder the thermistor to the pcb.

2.performed a PID with 10% fan on many times

3.i have routed both thermistor and heater to new locations on the main board, and updated the printer.cfg accordingly

it appears from the picture that it cannot regulate the hot end temperature during printing but can sit idle for a long time without issues. any advice is appreciated