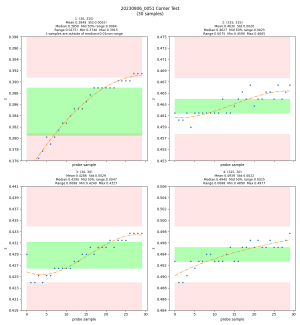

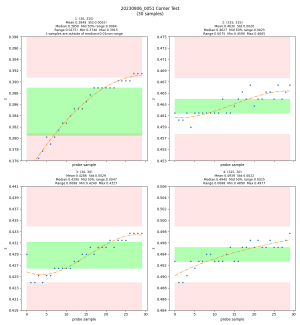

I just read in another thread that there is a tool on Github probe_accuracy_testprobe_accuracy_test

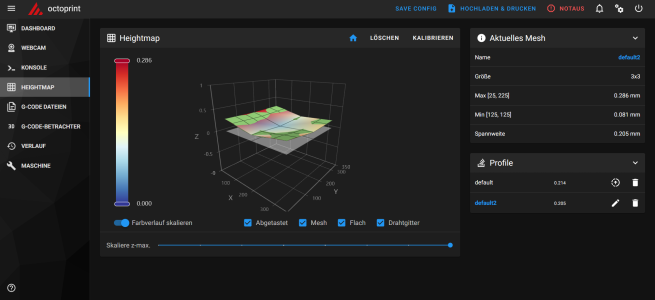

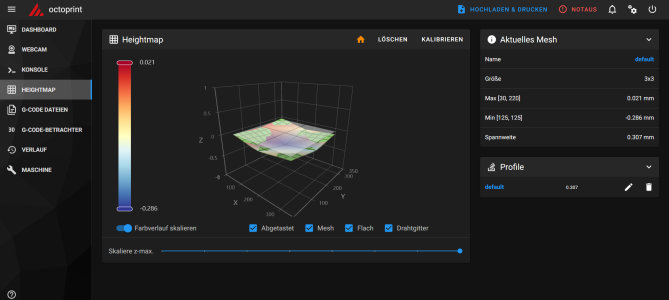

If I understand the graphic correctly, the Z belts are not the same

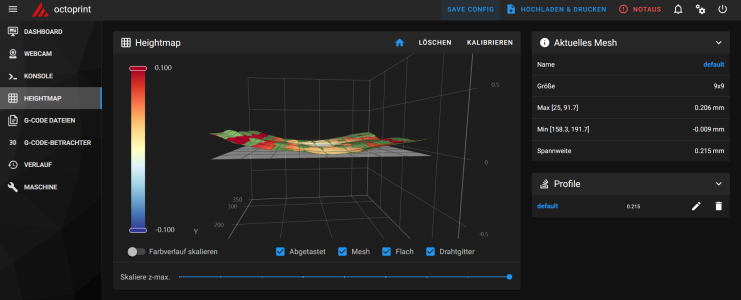

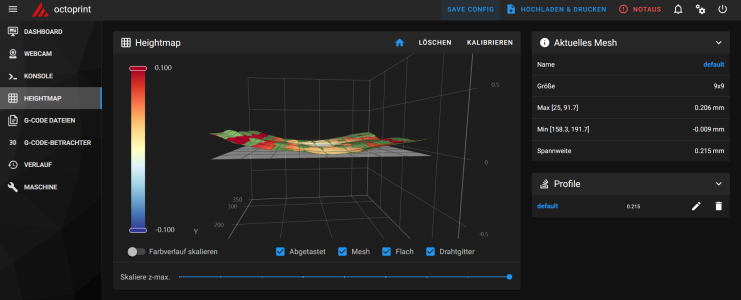

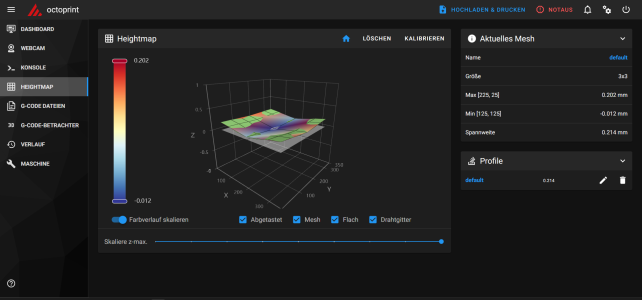

Leveling

4...3...2...1...Done

min max first last mean std count range drift

test

1:corner 30samples (30, 315) 0.405665 0.415665 0.415665 0.408165 0.408373 0.001740 30 0.01000 -0.00750

2:corner 30samples (315, 315) 0.503165 0.506915 0.506915 0.503165 0.504457 0.001333 30 0.00375 -0.00375

3:corner 30samples (30, 30) 0.434415 0.440665 0.440665 0.436915 0.435873 0.001471 30 0.00625 -0.00375

4:corner 30samples (315, 30) 0.513165 0.518165 0.516915 0.516915 0.515748 0.001269 30 0.00500 0.00000

--------------------------------------------------------------------------------

Take 20 probe_accuracy tests to check for repeatability

Test number: 20...19...18...17...16...15...14...13...12...11...10...9...8...7...6...5...4...3...2...1...Done

min max first last mean std count range drift

test

01: center 10samples 0.730665 0.735665 0.735665 0.731915 0.731915 0.001443 10 0.00500 -0.00375

02: center 10samples 0.730665 0.738165 0.738165 0.730665 0.731540 0.002361 10 0.00750 -0.00750

03: center 10samples 0.728165 0.735665 0.735665 0.729415 0.729915 0.002220 10 0.00750 -0.00625

04: center 10samples 0.728165 0.734415 0.734415 0.728165 0.729665 0.001936 10 0.00625 -0.00625

05: center 10samples 0.724415 0.730665 0.730665 0.724415 0.725165 0.001972 10 0.00625 -0.00625

06: center 10samples 0.729415 0.734415 0.734415 0.730665 0.730665 0.001443 10 0.00500 -0.00375

07: center 10samples 0.725665 0.733165 0.733165 0.728165 0.727665 0.002058 10 0.00750 -0.00500

08: center 10samples 0.719415 0.726915 0.726915 0.721915 0.721915 0.001954 10 0.00750 -0.00500

09: center 10samples 0.724415 0.730665 0.730665 0.725665 0.725665 0.001863 10 0.00625 -0.00500

10: center 10samples 0.721915 0.728165 0.728165 0.721915 0.722915 0.002024 10 0.00625 -0.00625

11: center 10samples 0.723165 0.731915 0.731915 0.723165 0.724915 0.002582 10 0.00875 -0.00875

12: center 10samples 0.724415 0.730665 0.730665 0.725665 0.725790 0.001811 10 0.00625 -0.00500

13: center 10samples 0.723165 0.731915 0.731915 0.725665 0.725540 0.002462 10 0.00875 -0.00625

14: center 10samples 0.724415 0.730665 0.730665 0.724415 0.726040 0.001773 10 0.00625 -0.00625

15: center 10samples 0.719415 0.725665 0.725665 0.720665 0.720915 0.001748 10 0.00625 -0.00500

16: center 10samples 0.715665 0.723165 0.723165 0.718165 0.717540 0.002145 10 0.00750 -0.00500

17: center 10samples 0.714415 0.723165 0.723165 0.714415 0.716790 0.002462 10 0.00875 -0.00875

18: center 10samples 0.715665 0.721915 0.721915 0.716915 0.716790 0.001905 10 0.00625 -0.00500

19: center 10samples 0.716915 0.725665 0.725665 0.718165 0.718665 0.002582 10 0.00875 -0.00750

20: center 10samples 0.716915 0.725665 0.725665 0.718165 0.719040 0.002433 10 0.00875 -0.00750

Your probe config uses median of 3 sample(s) over 20 tests

Below is the statistics on your median Z values, using different probe samples

mean min max std range sample_count

0 0.729915 0.721915 0.738165 0.004684 0.016250 1

1 0.727353 0.719415 0.735040 0.004803 0.015625 2

2 0.724790 0.716915 0.731915 0.004969 0.015000 3

3 0.724478 0.716290 0.731290 0.005000 0.015000 4

4 0.724228 0.715665 0.730665 0.005037 0.015000 5

5 0.724103 0.715665 0.731290 0.005002 0.015625 6

6 0.724040 0.715665 0.731915 0.005067 0.016250 7

7 0.724009 0.715665 0.731915 0.005115 0.016250 8

8 0.723977 0.715665 0.731915 0.005166 0.016250 9

9 0.724009 0.715665 0.731915 0.005115 0.016250 10

--------------------------------------------------------------------------------

Take 100 samples in a row to check for drift

min max first last mean std count range drift

test

center 100samples 0.715665 0.723165 0.723165 0.720665 0.718478 0.001735 100 0.0075 -0.0025