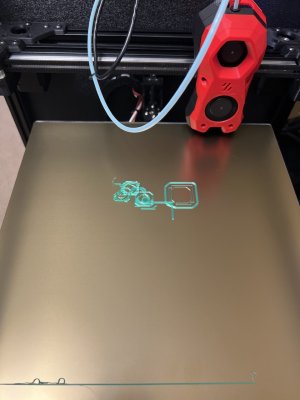

Hard to see the upper left idler, but that looks ok to me. Not going over the plastic (I think that's what @Sanity Agathion wanted to check); it's an easy, common error to make.

VORON Design

Register a free account today to become a member! Once signed in, you'll be able to participate on this site by adding your own topics and posts, as well as connect with other members!

z tilt issue

- Thread starter Wesley910

- Start date