Velychkin

New member

- Printer Model

- 2.4

- Extruder Type

- Clockwork 2

- Cooling Type

- Stealthburner

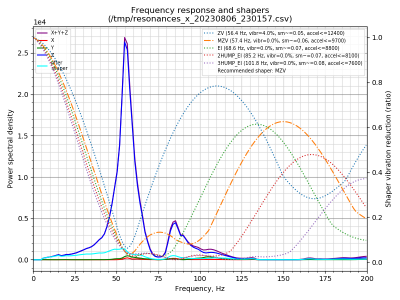

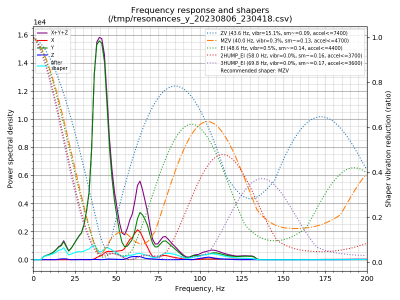

I've got Voron 2.4 300. Input shaper recommendations are nearly 9k on X axis and 4.5 on Y axis. Max accelerations according to ellis3dp guide is 30k. Is it OK to use accelerations higher than 4.5k (for example 10-15k) for travel moves, infill or even inner walls?