TaffoFox

Member

- Printer Model

- Trident 250

- Extruder Type

- Clockwork 2

- Cooling Type

- Stealthburner

Hi all.

I am posting this here instead of slice/print help, as I believe this is more of a mechanical issue at this point.

I finished my Trident 250 build recently, and I would love to get it to be printing more parts in ABS, however I cannot get nice printing results. The walls constantly have some form of artifacts on it, either wavy or rippling, and makes prints look horrible. I am still using my Switchwire at the moment which can push higher accelerations at better quality.

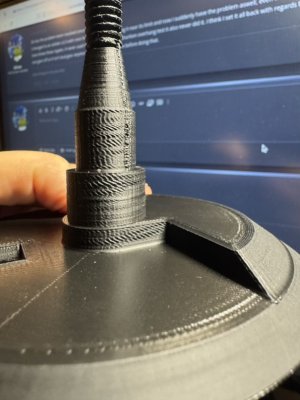

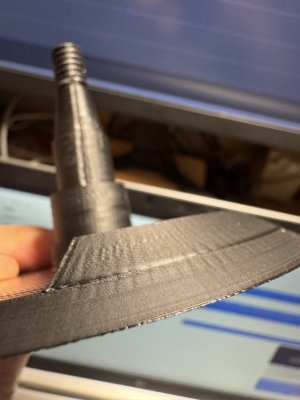

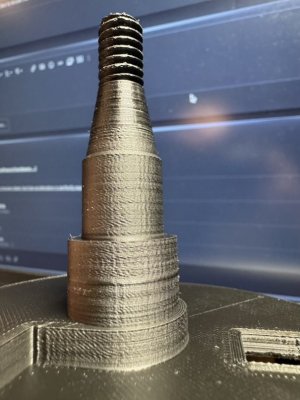

What my prints look like:

As can be seen, I get inconsistent rippling, ringing and "VFA like" artifacts (I'm unsure whether it is actually VFA related or not). Rippling seems to be worse at angles, where one stepper is doing all the work. These prints were done at 2000mm/s^2 acceleration with MZV input shaper enabled. I believe SCV was 5 and printing speed at 100mm/s.

Things I have tried, but has not helped my issues.

Not sure what has gone so wrong. I have a janky Switchwire which prints miles better at even faster speeds!

I have used help tickets, however we have not found a resolution for my problems. I hope that in posting it here, we can have an open discussion where everyone can see what is being tried, and what has been tried so far. Perhaps it can even be used as an example to help other people with similar issues.

Thanks in advance

I am posting this here instead of slice/print help, as I believe this is more of a mechanical issue at this point.

I finished my Trident 250 build recently, and I would love to get it to be printing more parts in ABS, however I cannot get nice printing results. The walls constantly have some form of artifacts on it, either wavy or rippling, and makes prints look horrible. I am still using my Switchwire at the moment which can push higher accelerations at better quality.

What my prints look like:

As can be seen, I get inconsistent rippling, ringing and "VFA like" artifacts (I'm unsure whether it is actually VFA related or not). Rippling seems to be worse at angles, where one stepper is doing all the work. These prints were done at 2000mm/s^2 acceleration with MZV input shaper enabled. I believe SCV was 5 and printing speed at 100mm/s.

Things I have tried, but has not helped my issues.

- Replaced idlers and pulleys for Gates genuine, using the BOM bearings and belts.

- Replaced linear rails on the motion system. Using another set of LDO rails with good tolerances. They are greased well.

- Replaced extruder 3 times. I have tried an LGX lite and 2x CW2s with high quality gears. Have tried with different amounts of backlash to ensure it wasn't too tight.

- Relocated printer, tried different types of floors.

- Changed multiple printer settings, such as SCV, IS, microsteps, stepper driver specific settings, etc.

- Changed multiple gcode settings, like speed, acceleration, pressure advance, flow rate, etc. Changing speeds just changes how the artifacts look, but don't go away.

- Tried multiple belt tensions, making sure it is equal every time.

- Tried many filament types, including PLA with panels off.

- Rebuilt motion system entirely, 3-4 times. Including checking for squareness, which was fine

- Tried multiple devices for measuring resonances, such as an onboard CAN adxl and a dedicated adxl mounted to the toolhead.

- Checking to make sure every single bolt was tight and had not loosened with the initial heat cycles.

- Putting the printer through 100h+ of use despite mediocre results, hoping to "break it in".

Not sure what has gone so wrong. I have a janky Switchwire which prints miles better at even faster speeds!

I have used help tickets, however we have not found a resolution for my problems. I hope that in posting it here, we can have an open discussion where everyone can see what is being tried, and what has been tried so far. Perhaps it can even be used as an example to help other people with similar issues.

Thanks in advance

Attachments

Last edited: