- Printer Model

- voron 2.4

- Extruder Type

- Clockwork 2

- Cooling Type

- Stealthburner

hello, I have by place built a voron 2.4,

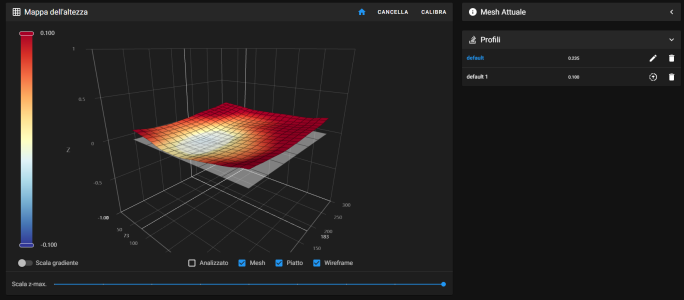

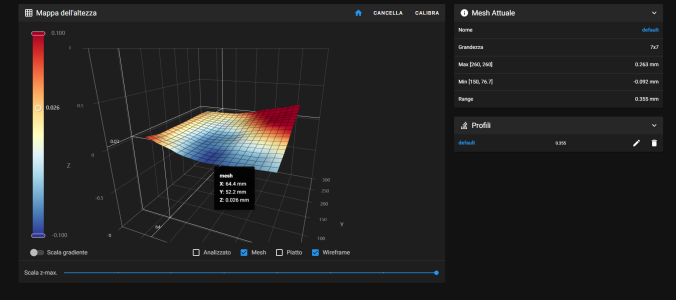

and I have a problem with the plate mesh.

I've tried everything but I can't get a perfect first layer.

can anyone give me any advice?

and I have a problem with the plate mesh.

I've tried everything but I can't get a perfect first layer.

can anyone give me any advice?