almightyjes

Member

i want to do some upgrades but i have gotten stuck.

controller board is a Fysetc Spider v2.3

for the upgrade i got a "canbus expander for spider" and "SB CAN TH"(stealthburner CAN toolhead)

i have to be honest, im not sure where i am at now.

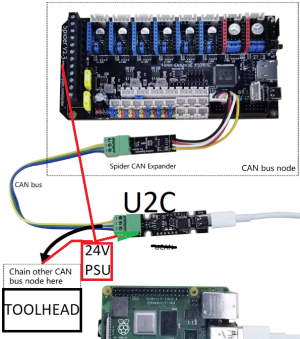

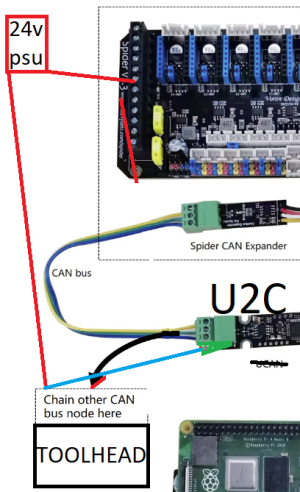

i got a BTT U2C v2.1, since i thought i needed it, but im pretty sure i bricked that, cant get it to dfu mode, but from what i understand i dont need U2C board with the spider board + CAN expander but klipper CAN bridge.

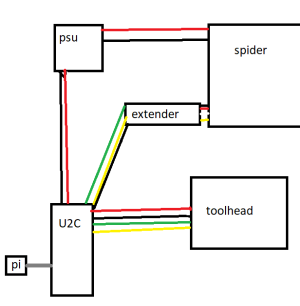

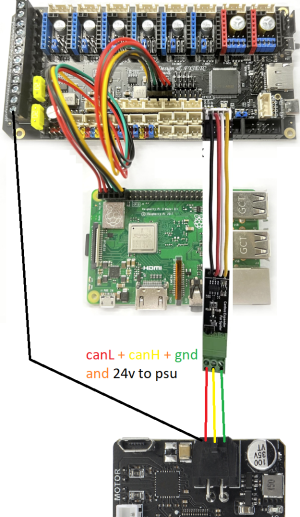

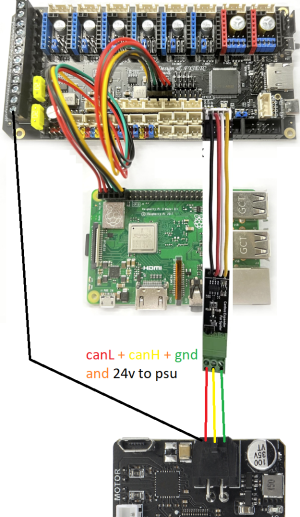

what i want to do is go from toolhead board to Can expander from can expander to spider board from spider board to rpi 4b but not using can, i will try and illustrate it here:

hope this is possible

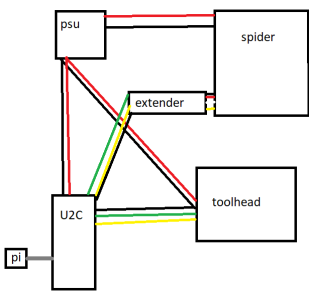

EDIT: so what i think im gonna do is this

github.com

Can someone confirm if this is what i want, but for spider board and sb can th instead of octopus and sb2040

github.com

Can someone confirm if this is what i want, but for spider board and sb can th instead of octopus and sb2040

controller board is a Fysetc Spider v2.3

for the upgrade i got a "canbus expander for spider" and "SB CAN TH"(stealthburner CAN toolhead)

i have to be honest, im not sure where i am at now.

i got a BTT U2C v2.1, since i thought i needed it, but im pretty sure i bricked that, cant get it to dfu mode, but from what i understand i dont need U2C board with the spider board + CAN expander but klipper CAN bridge.

what i want to do is go from toolhead board to Can expander from can expander to spider board from spider board to rpi 4b but not using can, i will try and illustrate it here:

hope this is possible

EDIT: so what i think im gonna do is this

GitHub - akhamar/voron_canbus_octopus_sb2040

Contribute to akhamar/voron_canbus_octopus_sb2040 development by creating an account on GitHub.

Last edited: