Hey all,

Wondering if any have ran across this issue. A couple weeks ago my printhead came down hard on the bed, made a lot of noise so I hit Emergency Stop on my 2.4v2. After rehoming and at the Zprobe it crashes again. Something odd I noticed, the gantry was almost touching the bed... Somthing was awry.

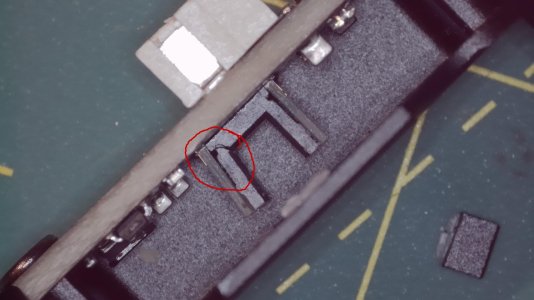

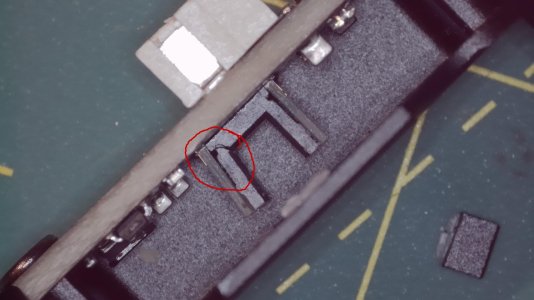

SO, I take apart the PH and moving down to the Chaoticlab Tap v2. Remove that from the X rail carriage and turn on the microscope. I see this:

I originally ordered this Tap V2 July of 2024. I installed the Tap on my machine in July 2025 before I got the klipper kinematics config straightened out, yaknow dumb stuff like homing directions properly set and sensorless homing configured properly, etc.

So, doing what I do, everything working awesome for about 3 months. Then this bed crash a couple weeks ago. SO, I intend to send an email to chaoticlab support. That was a challenge finding their email address. I run across some reference to them being owned by BIQU so I send an email to their tech support, including these pictures as well. BIQU responds they are on vacation/holiday and I should try again tomorrow. No joke. Try an email again tomorrow.

You'll notice from the pictures that the retainer tab is completely sheared off. Like it was snapped clean and the Omron sensor (genuine) EE-SX4320 is cracked. There's also a blown out 0.1u ohm resistor blown on the PCB. Presumably the cause of the initial crash. (I'm always finding the small things cause the biggest problems)

So I did, I emailed again the next day, no reply for 24 hours (china time). I get an email back asking for my order number (amazon) so I provided it, wait 24 hours. Reply comes back from BIQU: (paraphrased) You're out of warranty because date of purchase was , unable to process warranty claim. Timespan: Oct. 6 through Oct. 8th. NO reply from

support@chaoticlab.xyz yet.

Anyhow, thanks for reading. Just an FYI to a possible consideration of a design flaw or oversight.

If anyone would like to discuss... feel the freedom.

"sincerely" hehe