m00dawg

Well-known member

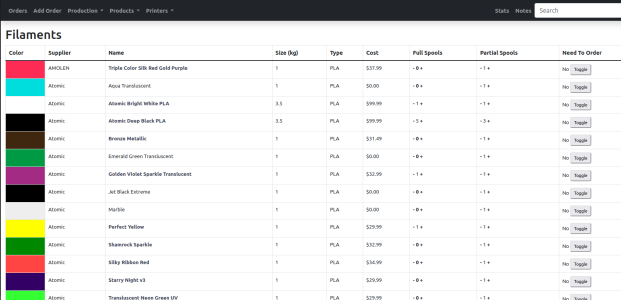

My small print farm is now up to 5 printers (including 2 Vorons) and I recently inventoried all my filament spools and added a small feature to my print farm web app to track my spool inventory a bit better. But that got me thinking - if I slapped a barcode on spools and had a fancy barcode scanner, I could scan spools in and out as I swap them among printers. I think that's probably over-complicating things for what I do given probably 75% of the time I'm using the same filament on each printer. On my V0, it's black ABS. 2 of my Mk3s it's black PLA, 1 Mk3 it's black PETG and my Voron 2.4 it's black or white PLA. But even then, if I empty a spool and scan in a new one, I could have that auto-update my inventory and just make things easier. Still probably not worth the time to integrate all that and buy a fancy barcode labeller and scanner.

I was curious though what other folks who have small to medium sized print farms are doing to track filament spools?

I was curious though what other folks who have small to medium sized print farms are doing to track filament spools?