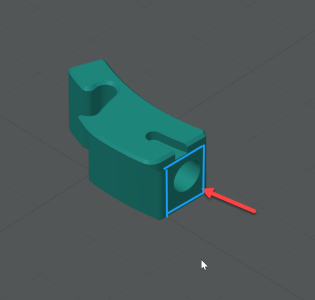

So my printer was working great...until it wasn't. I ran several prints the other day that came out great & started to run a new job in the morning. The extruder started making nasty grinding noises and barely shoved an plastic at all. WTF? I have taken the CW2 apart and reassembled several times now; nothing looks amiss that I can see. Everything spins smoothly & freely. I have pulled the motor and run it loose and it spins fine. I've swapped filament (two different PLAs) and three different nozzles on my Revo--confirmed no clogs. I can issue an extrude command from KlipperScreen or Fluidd and it works normally. When I run my filament load macro or try to actually print it starts up with the grinding; it even does this with no filament loaded. I'm at a loss and welcome any ideas.

VORON Design

Register a free account today to become a member! Once signed in, you'll be able to participate on this site by adding your own topics and posts, as well as connect with other members!

CW2 Gone Bad

- Thread starter claudermilk

- Start date