greendog

Member

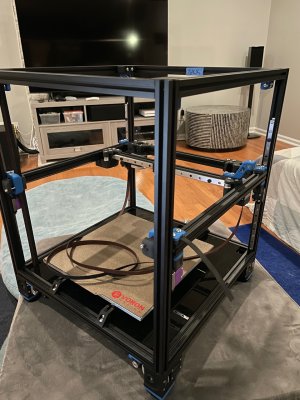

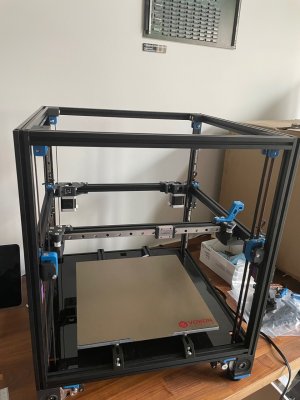

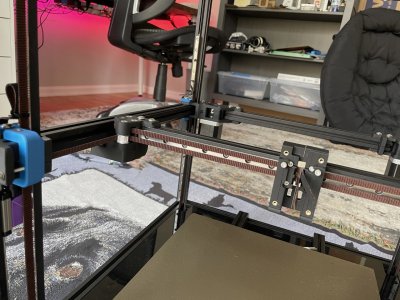

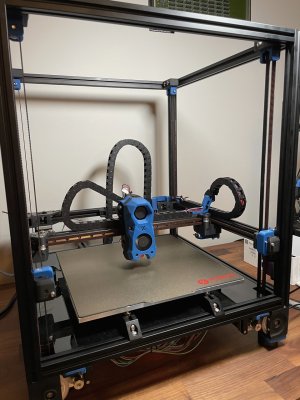

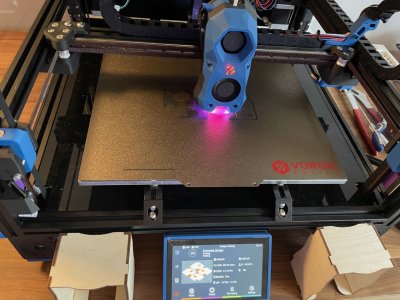

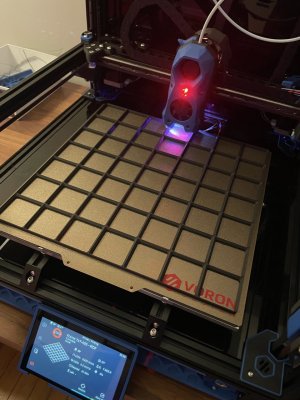

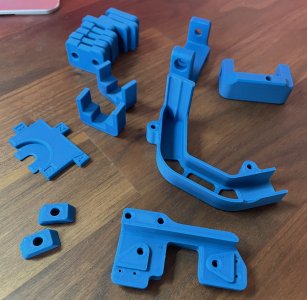

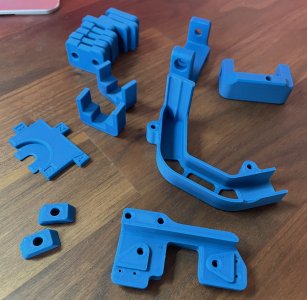

My Formbot 300mm kit arrives this Friday! I've been slowly printing functional parts on one of my two heavily modified Anycubic Mega-S printers with a super high-tech cardboard enclosure (see pics). Never tried ABS before but it's been really smooth sailing (eSun ABS+ Blue). The only issue I ran into was bridging... after a lot of experimentation I found that an absurdly slow speed (5mm/sec) results in perfect bridges. Printing at 240ºC, bed 100ºC, fan @ 40%, bridge fan @ 80%. Almost done the accent color functional parts, starting on the black parts tomorrow. I'm using Gabriele Colaiuda's "Voron 2.4 R2 Print Parts" google spreadsheet to select and track my prints.

Still getting my head wrapped around various options, but I feel like I might want to try to go with Tap right from the start rather than the inductive probe or Klicky. Also might try the Canbus mod rather than the standard wiring, though it sounds like lots of people have canbus connectivity issues.

Gonna be a fun month or two!

Still getting my head wrapped around various options, but I feel like I might want to try to go with Tap right from the start rather than the inductive probe or Klicky. Also might try the Canbus mod rather than the standard wiring, though it sounds like lots of people have canbus connectivity issues.

Gonna be a fun month or two!

Last edited: