lukics

Member

I have a freshly built 2.4 350x350 from FormBot.

I have questions regarding the gantry and quad gantry leveling:

I have questions regarding the gantry and quad gantry leveling:

- Is it normal that the gantry drops a few milimeters when the z-motors are powered off? (on the side of the gantry motors)

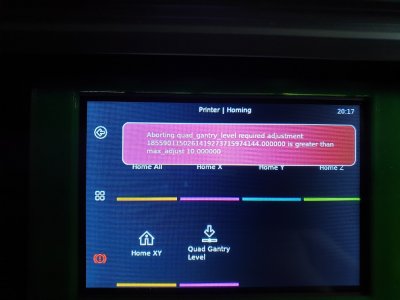

- how many passes of quad gantry level are regular? I have more or less 3+ passes, sometimes (seldom) also giving up with an error of too many reties.

- Is it ok when during the quad gantry leveling the probe retires are done ("Probe samples exceed tolerance. Retrying...")? I tried the inductive probe, but also the installed Kklicky behaves the same.

- Should I heat up the bed and then do quad gantry leveling, or is it even ok to do leveling during heating up?

Last edited: