Bane

New member

- Printer Model

- 2.4r2

- Extruder Type

- Clockwork 1

- Cooling Type

- Afterburner

Hi all,

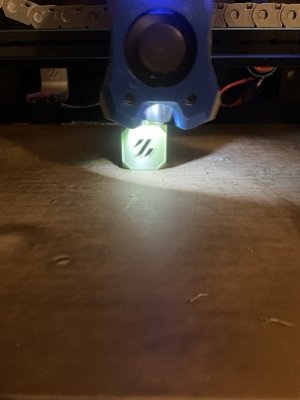

I need help with a printing issue. What would cause the below?

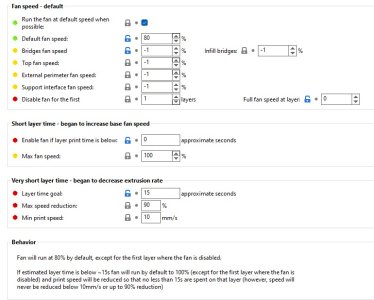

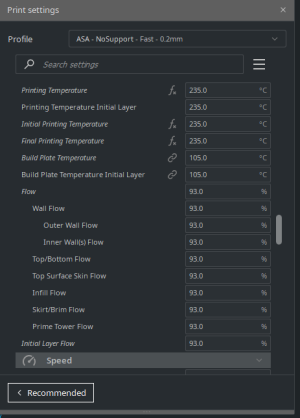

This is Polymaker ASA printing at 245 with 110 bed temp and 80% constant fan. I am really having a hard time figuring out what may be the issue. I have checked belt tension and checked tightness of everything.

I really don't know what to do next. Any assistance would be greatly appreciated.

I need help with a printing issue. What would cause the below?

This is Polymaker ASA printing at 245 with 110 bed temp and 80% constant fan. I am really having a hard time figuring out what may be the issue. I have checked belt tension and checked tightness of everything.

I really don't know what to do next. Any assistance would be greatly appreciated.