BigBadWolf

Member

- Printer Model

- Voron 2.4

- Extruder Type

- Clockwork 2

- Cooling Type

- Stealthburner

Hey guys,

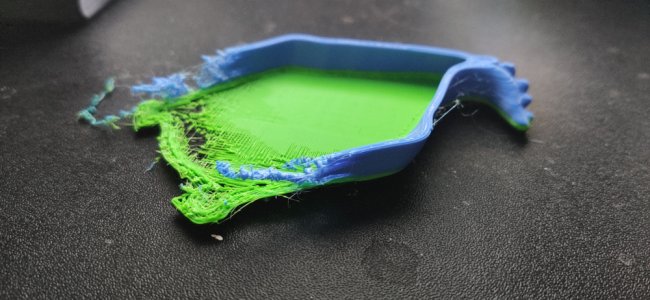

I got another pretty strange problem with my Voron 2.4 with a Stealthburner. The extruder skippes and makes clicking-noises, but only when in front of a centered print. The backside of the layers is printed fine, as you can see in the pictures. The testprint seen was printed in PETG in the middle of the bed.

The problem exists even when not printing: the printhead extrudes only when in the "back half" of the printer, in the front it will only click but not extrude any filament. The higher the gantry moves, the far back the problem remains. Small objects can be printed in the back half of the printbed, tall objects will get a "broken front", worse and worse as the gantry moves higher.

Everything I tried so far:

- replaced the reverse bowden tube with a fresh capricorn (to lower friction)

- removed the filament runout sensor

- switched filament (ABS, ABS+, ASA, PETG, PLA, PLA+)

- rebuild the extruder, swapped the extruder gears and stepper motor

- removed all custom settings from the Klipper config: Pressure Advance, Input Shaper, all set to stock-settings

- checked all wire crimps and the mainboard connectors for the extruder/hotend

- checked nozzle-temperature empty and while extruding

- checked belt-tension and lubed all moving parts

- replaced the nozzle

Nothing made a difference, the extrusion remains bad and the extruder starts clicking, when the printhead comes to the front. The Rapido hot-end melts every material like a charm, when the filament is pushed through by hand - so this does not seem to be the problem either.

My question: what am I missing? Does someone have a similar problem or an idea what to check next?

I got another pretty strange problem with my Voron 2.4 with a Stealthburner. The extruder skippes and makes clicking-noises, but only when in front of a centered print. The backside of the layers is printed fine, as you can see in the pictures. The testprint seen was printed in PETG in the middle of the bed.

The problem exists even when not printing: the printhead extrudes only when in the "back half" of the printer, in the front it will only click but not extrude any filament. The higher the gantry moves, the far back the problem remains. Small objects can be printed in the back half of the printbed, tall objects will get a "broken front", worse and worse as the gantry moves higher.

Everything I tried so far:

- replaced the reverse bowden tube with a fresh capricorn (to lower friction)

- removed the filament runout sensor

- switched filament (ABS, ABS+, ASA, PETG, PLA, PLA+)

- rebuild the extruder, swapped the extruder gears and stepper motor

- removed all custom settings from the Klipper config: Pressure Advance, Input Shaper, all set to stock-settings

- checked all wire crimps and the mainboard connectors for the extruder/hotend

- checked nozzle-temperature empty and while extruding

- checked belt-tension and lubed all moving parts

- replaced the nozzle

Nothing made a difference, the extrusion remains bad and the extruder starts clicking, when the printhead comes to the front. The Rapido hot-end melts every material like a charm, when the filament is pushed through by hand - so this does not seem to be the problem either.

My question: what am I missing? Does someone have a similar problem or an idea what to check next?