VoronManiac

New member

In Voron User Mods this thoughtful article by Ellis talks about under bed fans and limiting power density to 0.4 watts per cm^2, imposing a limit of ~48% of max power for his setup. This causes painfully slow chamber heating times. I remember seeing similar references to limiting bed power dating back to 2015, specifically to non-tooling plate beds. WHERE DOES THIS NUMBER COME FROM?

Under bed fans can be used to increase the max chamber temperature, but if we just focus on just getting the chamber up to operating temp, this 0,4 W/cm^2 limitation seems to center around not wanting to permanently warp and "taco" the build plate. I'm not an expert, but from looking at a number of white papers and on line sources, the bed plate can be modeled as an unconstrained thin plate with thermal gradient between the faces. The bed plate will bow because of the gradient, but it should have no first order thermal stress and no permanent deformation. Also assume the bed is floating and not constrained by the frame.

Where the model starts to break down is when we start to consider edge effects where the heater pad on most of our printers does not extend to the edges of plate. Here we create an additional gradient that tends to constrain the heated central core. This might induce thermal stresses. It remains unclear if this stress could exceed the yield point of the Mic6 bed plate, but even this gradient is not large. Can anyone out there run a FEM sim for this?

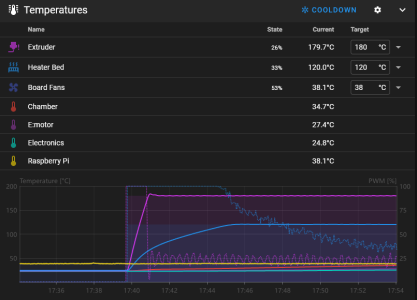

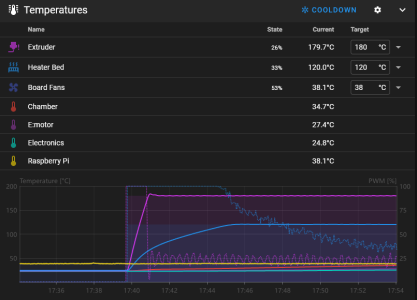

I've been running my 350x350 V2.4 at 100% bed power (600W) now for many years and have seen no bed warping or heater pad adhesive de-lamination issues. I am wondering if the correct strategy to bring the chamber up to temp is to blast as much air as possible both under and over the bed to max out the heater. Without under bed fans, my bed heater runs at full power for ~5.5 minutes and then starts to decrease as the bed approaches the target temp. Adding under and above cooling at that 5.5 minute mark could keep the heater at full power until the target chamber temp is achieved.

Under bed fans can be used to increase the max chamber temperature, but if we just focus on just getting the chamber up to operating temp, this 0,4 W/cm^2 limitation seems to center around not wanting to permanently warp and "taco" the build plate. I'm not an expert, but from looking at a number of white papers and on line sources, the bed plate can be modeled as an unconstrained thin plate with thermal gradient between the faces. The bed plate will bow because of the gradient, but it should have no first order thermal stress and no permanent deformation. Also assume the bed is floating and not constrained by the frame.

Where the model starts to break down is when we start to consider edge effects where the heater pad on most of our printers does not extend to the edges of plate. Here we create an additional gradient that tends to constrain the heated central core. This might induce thermal stresses. It remains unclear if this stress could exceed the yield point of the Mic6 bed plate, but even this gradient is not large. Can anyone out there run a FEM sim for this?

I've been running my 350x350 V2.4 at 100% bed power (600W) now for many years and have seen no bed warping or heater pad adhesive de-lamination issues. I am wondering if the correct strategy to bring the chamber up to temp is to blast as much air as possible both under and over the bed to max out the heater. Without under bed fans, my bed heater runs at full power for ~5.5 minutes and then starts to decrease as the bed approaches the target temp. Adding under and above cooling at that 5.5 minute mark could keep the heater at full power until the target chamber temp is achieved.