swiss3dc

New member

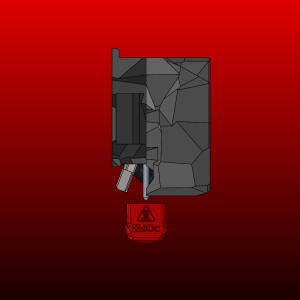

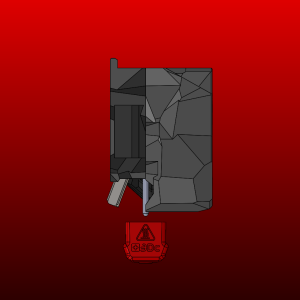

I've adapted the Stealthburner head (back & front) to implement the Bambulab heat sink (nice and light) with the Starlex DHB 24 hot-end in parallel for an easy access. As both heat blocks open parallel to the fan shroud, it makes it an easy tool free nozzle swap access.

Even better, to be tested, there is a second setup to implement within the same nozzle height, a 33mm nozzle melt zone to increase flow capacity to at least 33mm3/s.

Some heat blocks are designed to withstand a PT1000 temperature sensor and generally the NTC 100K 3950, with Microfit 3.0 connectors for ease of connexions.

STL and Step files available at present on Printables - swiss3dc

Any suggestions welcome, as I'm new here

Even better, to be tested, there is a second setup to implement within the same nozzle height, a 33mm nozzle melt zone to increase flow capacity to at least 33mm3/s.

Some heat blocks are designed to withstand a PT1000 temperature sensor and generally the NTC 100K 3950, with Microfit 3.0 connectors for ease of connexions.

STL and Step files available at present on Printables - swiss3dc

Any suggestions welcome, as I'm new here