Howdy all. I have an Ender 3 S1 Pro I bought last year, and enjoy. Got interested in building a Voron almost immediately due to the obvious advantages and good things I'd heard, but never expected to spend the money. Well, obviously, I did.

I've been going back and forth on what exactly I wanted to build for a while. Trident versus 2.4, obviously. Trident much easier to build, 2.4 being the "Iconic" Voron. Knew I wanted an LDO kit to simplify, and wanted a Rapido for the hot end.

I ended up wavering on the hot end, and went with a Revo voron. I haven't changed the nozzle on my ender, ever, but the simplicity convinced me. And if I end up tuning it to the point of needing more flow, its easy enough to print the replacement toolhead and swap over.

Ordered PIF on 2/4, with a 10 person queue. Got assigned Will on 2/6, and finalized the details. Added a set of TAP printed parts as well. Fabreeko was out of Trident kits, but had a shipment due on the 10th. On Discord they verified stuff was coming in so I went ahead and ordered the LDO Trident 300 kit, and a Revo Voron. Ordered the nozzle kit and TAP kit from matterhackers as well. Will got the PIF parts shipped by the 9th, the LDO kit showed up at Fabreeko and they slapped a shipping label on it. PIF arrived on Friday, the Trident kit on Saturday, and the MH order on Sat as well. Great turnaround for all of them.

Opened the LDO kit box, and found that they had included a Revo inside?! Jumped onto their website for the BOM, nope, no Revo listed. Checked the BOM included in the box, no Revo. Jumped onto discord and pinged Fabreeko and LDO. Fabreeko thought maybe they'd opened the box to include the one I ordered until I posted a picture of 2 side by side. Verdict: LDO simply screwed up. Their response: Bonus and enjoy! Fabreeko suggested I request a return on the one I bought. Yeah, I think I will. Its blue instead of red, but I can live with that. Apparently Im not the only one, someone else asked about the same thing.

Plans:

1: Build the thing

2: TAP

3: Sensorless homing XY

4: CANbus/Umbilical

5: ERCF (6? 9? Don't know yet. Mostly to be lazy and have hands off color choices rather than MMU, but will be used for both as needed)

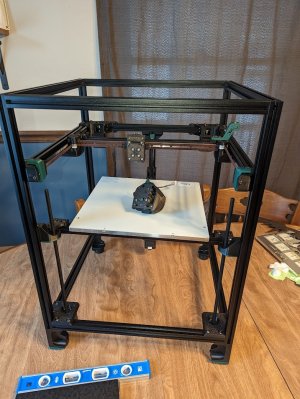

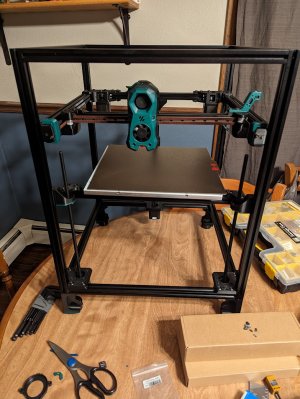

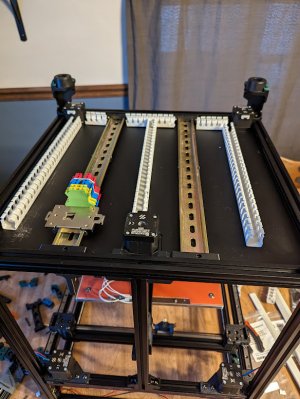

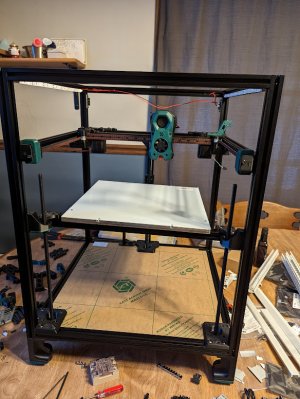

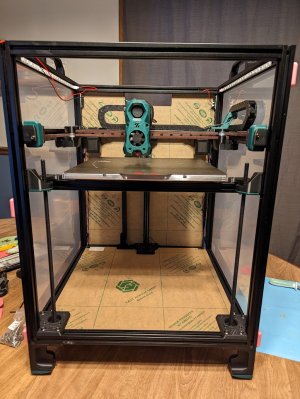

So I have the parts, time to start building!

Black frame kit, KVP Black primary color, KVP British Racing Green for accents.

I've been going back and forth on what exactly I wanted to build for a while. Trident versus 2.4, obviously. Trident much easier to build, 2.4 being the "Iconic" Voron. Knew I wanted an LDO kit to simplify, and wanted a Rapido for the hot end.

I ended up wavering on the hot end, and went with a Revo voron. I haven't changed the nozzle on my ender, ever, but the simplicity convinced me. And if I end up tuning it to the point of needing more flow, its easy enough to print the replacement toolhead and swap over.

Ordered PIF on 2/4, with a 10 person queue. Got assigned Will on 2/6, and finalized the details. Added a set of TAP printed parts as well. Fabreeko was out of Trident kits, but had a shipment due on the 10th. On Discord they verified stuff was coming in so I went ahead and ordered the LDO Trident 300 kit, and a Revo Voron. Ordered the nozzle kit and TAP kit from matterhackers as well. Will got the PIF parts shipped by the 9th, the LDO kit showed up at Fabreeko and they slapped a shipping label on it. PIF arrived on Friday, the Trident kit on Saturday, and the MH order on Sat as well. Great turnaround for all of them.

Opened the LDO kit box, and found that they had included a Revo inside?! Jumped onto their website for the BOM, nope, no Revo listed. Checked the BOM included in the box, no Revo. Jumped onto discord and pinged Fabreeko and LDO. Fabreeko thought maybe they'd opened the box to include the one I ordered until I posted a picture of 2 side by side. Verdict: LDO simply screwed up. Their response: Bonus and enjoy! Fabreeko suggested I request a return on the one I bought. Yeah, I think I will. Its blue instead of red, but I can live with that. Apparently Im not the only one, someone else asked about the same thing.

Plans:

1: Build the thing

2: TAP

3: Sensorless homing XY

4: CANbus/Umbilical

5: ERCF (6? 9? Don't know yet. Mostly to be lazy and have hands off color choices rather than MMU, but will be used for both as needed)

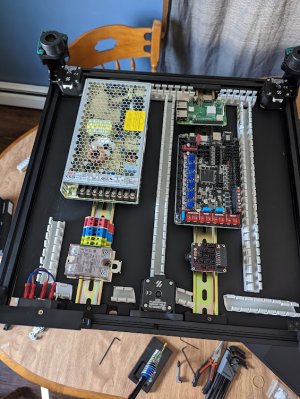

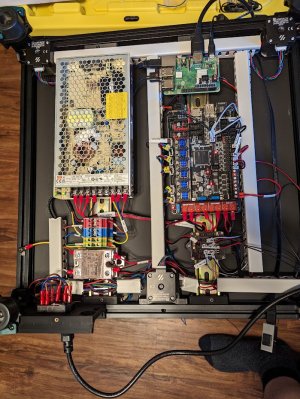

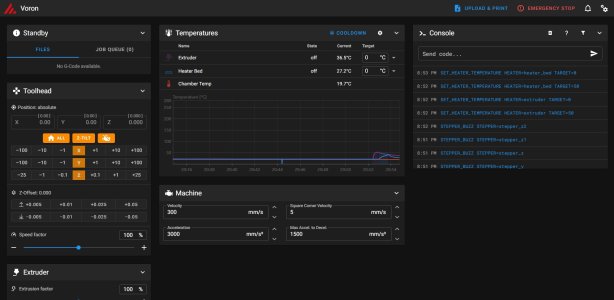

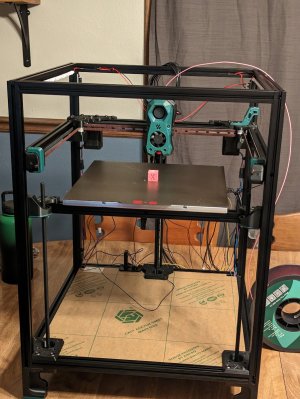

So I have the parts, time to start building!

Black frame kit, KVP Black primary color, KVP British Racing Green for accents.

Last edited: