Stefa168

Member

Hi, in these days I finished installing on my 2.4 the Stealthburner toolhead.

I am using a PCB by Hartk, in particular the two piece version.

Everything works fine, except for the neopixels.

In particular, the problem appears only if I have the heater cooling fan plugged in (in my case as I needed to use the AUX trace for the tachometer I inverted the two connections, but it shouldn't be an issue).

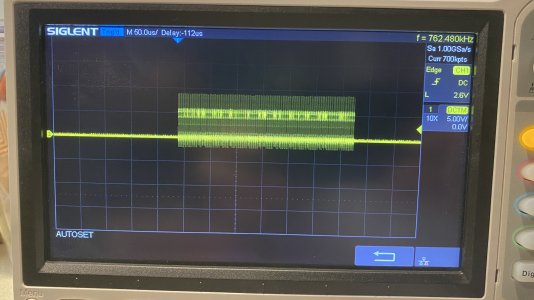

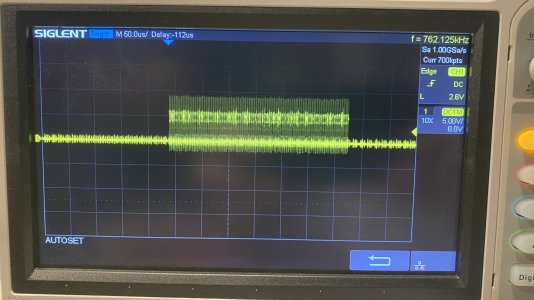

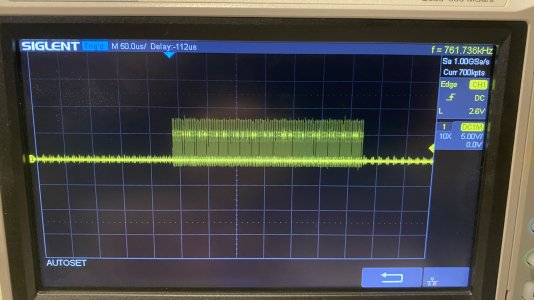

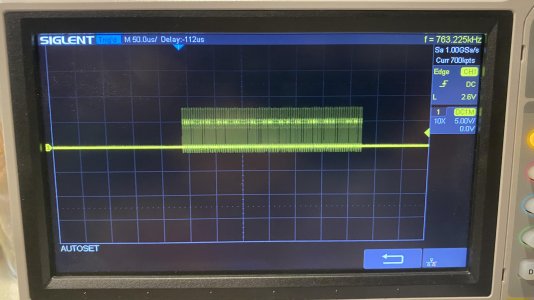

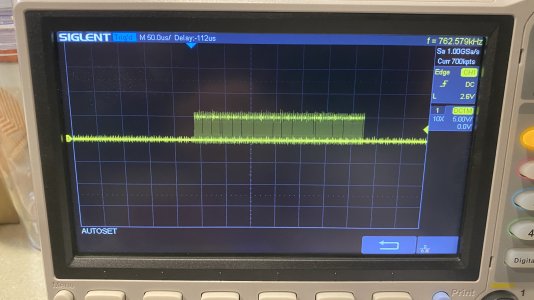

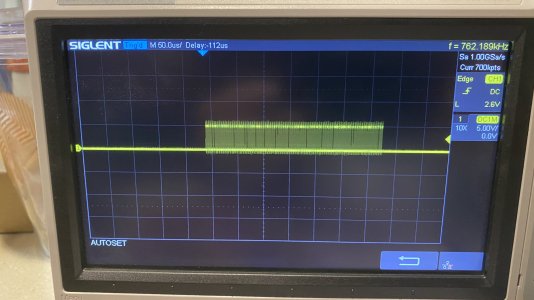

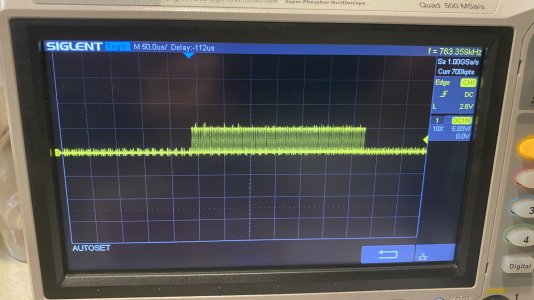

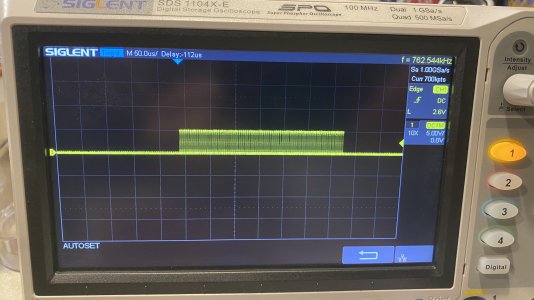

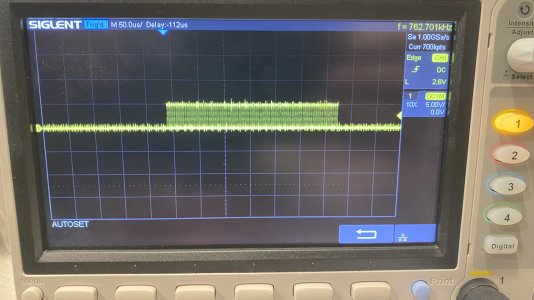

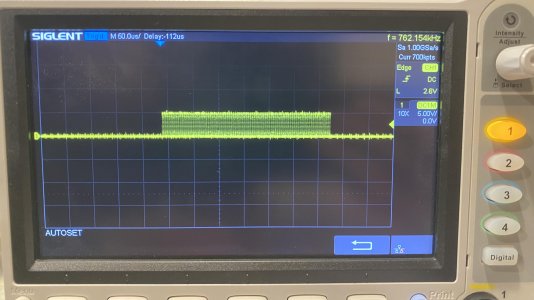

Here you can see the issue:

I have tried adding a 200 ohm resistor in series with the data line, but it didn't change the behaviour.

By chance, I touched the hotend with my bare fingers, and at first I thought that it was a bad connection.

However, when I began unscrewing the PCB from the stealthburner, I noticed that the issue disappeared as soon as I touched the screw with my allen key.

Here's a video showing what it is happening:

Could it be that there is some grounding issue, or that a capacitor is needed somewhere? I have some knowledge about electronics, and this looks like it could be a capacitor issue.

Any thought?

I am using a PCB by Hartk, in particular the two piece version.

Everything works fine, except for the neopixels.

In particular, the problem appears only if I have the heater cooling fan plugged in (in my case as I needed to use the AUX trace for the tachometer I inverted the two connections, but it shouldn't be an issue).

Here you can see the issue:

I have tried adding a 200 ohm resistor in series with the data line, but it didn't change the behaviour.

By chance, I touched the hotend with my bare fingers, and at first I thought that it was a bad connection.

However, when I began unscrewing the PCB from the stealthburner, I noticed that the issue disappeared as soon as I touched the screw with my allen key.

Here's a video showing what it is happening:

Could it be that there is some grounding issue, or that a capacitor is needed somewhere? I have some knowledge about electronics, and this looks like it could be a capacitor issue.

Any thought?