Run though the setup again, I think you missed somthing.

Z Offset Adjustment

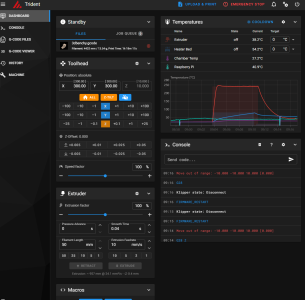

If you did not run PID tuning, set your extruder to 245C and heated bed to 100C and let the printer heat up for at least 15 minutes.

Initial / Simple Process

Preparation

- V1/Trident: Run a G28, and then a Z_TILT_ADJUST, and then another G28.

- V2: Run a G28, and then a QUAD_GANTRY_LEVEL, and then another G28.

- All others: Run a G28.

- Move the nozzle to the center of the bed if it is not already.

- Clear any stored bed meshes with BED_MESH_CLEAR

Run Z_ENDSTOP_CALIBRATE (V0, Trident, V2) or PROBE_CALIBRATE (Switchwire)

Slowly move the nozzle toward the bed by using TESTZ Z=-1 until the nozzle is relatively close to the bed, and then stepping down with TESTZ Z=-0.1 until the nozzle touches a piece of paper on top of the build plate. If you go too far down, you can move the nozzle back up with: TESTZ Z=0.1. Once you are satisfied with the nozzle height, run ACCEPT and then SAVE_CONFIG.

Important: Klipper assumes that this process is being done cold. If being performed hot, do an additional TESTZ Z=-0.1 before accepting.

If an “out of bounds” error occurs, send Z_ENDSTOP_CALIBRATE, ACCEPT, and then SAVE_CONFIG. This will redefine the 0 bed height so you will be able to get closer.

V2: If you get this error it likely means that the shaft for your Z Endstop is too long and may catch on the print head during a print. It is best to cut the shaft or raise the bed (with a washer, for instance) so that it is within 1mm of the build surface.