Samiamjohnson1

Member

Hey guys. I am in the process of designing a custom 3d printer from scratch.

BUT…..

I have no idea what I am doing lol.

I work as a maintenance mechanic at a manufacturing company, so I am familiar with industrial machines. I have been printing on an Ender 3 Neo that I have modified to print 300 degrees to print carbon fiber. But I am not happy with the size limitations. So, I have decided to create a 24”x36” 3d printer.

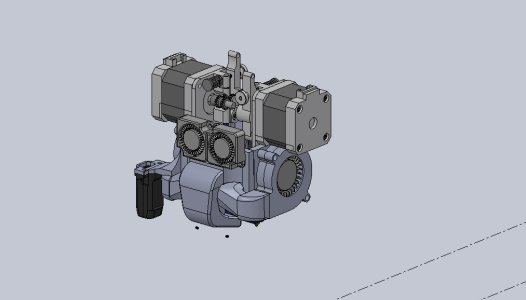

So far, I have designed a dual extruder head using the Micro Swiss direct drive heads. It has 5 fans on the extruder.

I also want to include a self-leveling bed driven by 3-stepper motors. So, I am up to 9 stepper motors including the dual z-axis.

So, I was planning on using the octopus board because it supports 9 motors. But it seems like there are several options and it is not making sense with my skill level to what I really need.

I also read what I think is an option to run the extruders off USB instead of a ribbon.

So I guess my question is what would you recommend for the board, and controllers, what do I need to put together to make this all work?

Any suggestions would be amazing

Thanks

Sam Johnson

BUT…..

I have no idea what I am doing lol.

I work as a maintenance mechanic at a manufacturing company, so I am familiar with industrial machines. I have been printing on an Ender 3 Neo that I have modified to print 300 degrees to print carbon fiber. But I am not happy with the size limitations. So, I have decided to create a 24”x36” 3d printer.

So far, I have designed a dual extruder head using the Micro Swiss direct drive heads. It has 5 fans on the extruder.

I also want to include a self-leveling bed driven by 3-stepper motors. So, I am up to 9 stepper motors including the dual z-axis.

So, I was planning on using the octopus board because it supports 9 motors. But it seems like there are several options and it is not making sense with my skill level to what I really need.

I also read what I think is an option to run the extruders off USB instead of a ribbon.

So I guess my question is what would you recommend for the board, and controllers, what do I need to put together to make this all work?

Any suggestions would be amazing

Thanks

Sam Johnson