vojta.rasp

New member

- Printer Model

- Voron 2.4 350x350

- Extruder Type

- Clockwork 2

- Cooling Type

- Afterburner

Hi all,

Printer Voron 2.4 350x350, Manta, CB1, Tap, CAN; used filament PLA (which works perfectly on Trodon and ancient Ender)

I am newbie to the voron users community. I am struggling to make the 1st layer being consistently adhering across the bed on my "build in progress" printer.

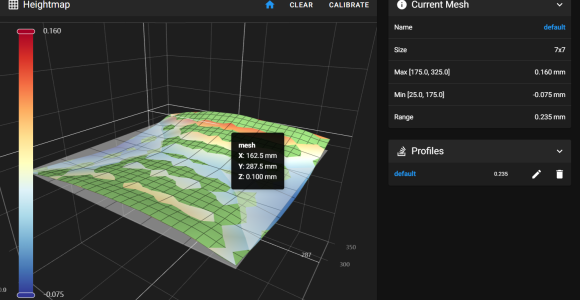

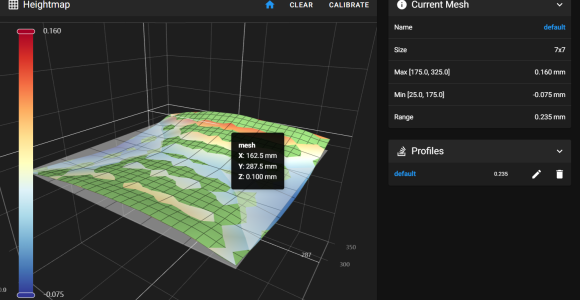

I tried several things, with frustration I removed the magnetic self adhesive foil and make a heightmap on the bare heatbed (result attached).

Prior beforementioned I tried the X offset tuning several times (incl. finetuning during the print) but all the time the same result. on some places the layer stick on some other does not.

I tried even 11x11 mesh with bicubic algorithm in order to identify the problem.

I measured rails against the gantries and they are perpendicular with higher than 0.1mm accuracy

Double checked the belt tension.

All rails are moving smoothly and rails/carriages are lubricated.

Frame was check for its squareness during the build all the time incl. measuring the diagonals

any clue what to check, or try...

Printer Voron 2.4 350x350, Manta, CB1, Tap, CAN; used filament PLA (which works perfectly on Trodon and ancient Ender)

I am newbie to the voron users community. I am struggling to make the 1st layer being consistently adhering across the bed on my "build in progress" printer.

I tried several things, with frustration I removed the magnetic self adhesive foil and make a heightmap on the bare heatbed (result attached).

Prior beforementioned I tried the X offset tuning several times (incl. finetuning during the print) but all the time the same result. on some places the layer stick on some other does not.

I tried even 11x11 mesh with bicubic algorithm in order to identify the problem.

I measured rails against the gantries and they are perpendicular with higher than 0.1mm accuracy

Double checked the belt tension.

All rails are moving smoothly and rails/carriages are lubricated.

Frame was check for its squareness during the build all the time incl. measuring the diagonals

any clue what to check, or try...