WhiteWulfe

Well-known member

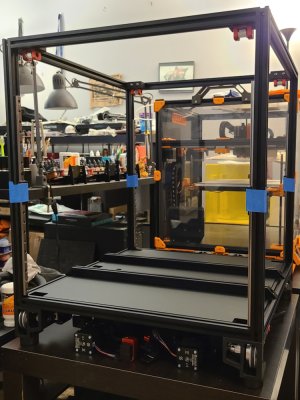

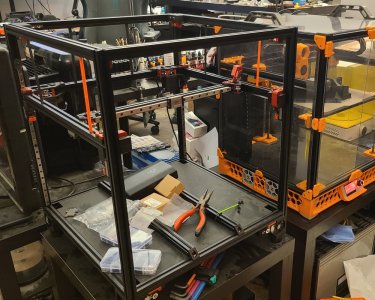

Got the living room rearranged so there's a spot for it, and UPS says the kit will be delivered tomorrow alongside other goodies, so why not get the thread rolling. So yup, this is going to be my second 3d printer ever, with the Trident having been the first. I don't really plan on doing all that many mods during the build let alone after. It's a good design, has many things already taken into consideration, and I look at my printers more like tools that require occasional maintenance and calibration as opposed to something to constantly tinker or fiddle with.

So what colours am I planning on going with? Matter3D's Matte Black ABS with Matte Orange ABS accents is what I'm going with, mainly because they're colours I rather like, and also because they make an orange I rather like the look of. Sparta3D's Bright Orange is a lovely sparkle ABS+, and Polymaker ABS is absolutely wonderful to work with, but both of them are just too yellow for my taste. A quick glance of things indicates these should work fairly well with the Chaotic Lab CNC parts that I won during a holiday giveaway.

What mods are we looking at, anyways?

- Nevermore

- Bed fans

- Lightweight Labware Kinematic Mount

- Chaotic Lab CNC parts kit

- Klicky PCB (eventually)

- Stealthburner 2 piece PCB

- VEFACH

- chamber thermistor

- Sexbolt (if needed, have one lying around anyways)

- purge bucket of some sort (seems like a nice quality of life thing, since cleaning scraps off the bottom of a v2.4 isn't as easy as a Trident)

- Sturdy handles (I like the ones my Trident has)

Might be one or two more that I forgot about putting into the list like panel clips or different hinges for the doors

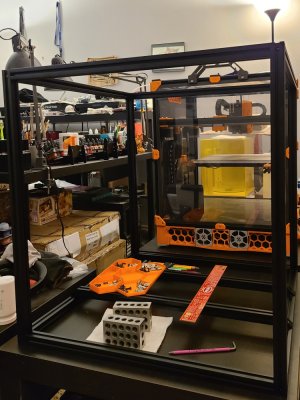

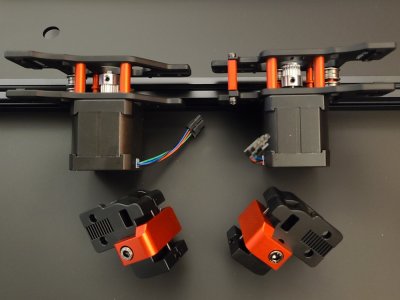

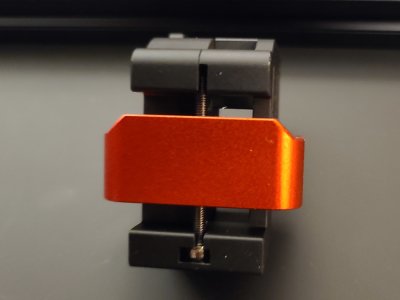

^The Chaotic Lab CNC parts kit. Comes with Rev 1 feet and AB idlers, but thankfully the z motor mounts are compatible with Rev 2 feet, which I prefer the look of. Hopefully at some point a Rev 2 AB idler update will be offered. I've had a few ask my thoughts on these parts, and in all honesty, I don't know what to say. I like them, they look nice, and I hope I'll be able to have an actual opinion once I've started assembling various things.

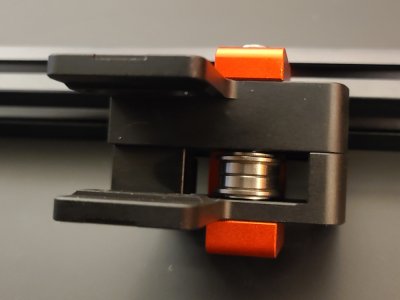

^Quick test of how the chosen ABS colours work with the red anodizing. I'm rather certain they'll work together, doubly so because they generally won't be next to each other anyways.

Normally there'd be a pic of printed parts ready to go for the build posted here, but Foxyfluff had a wire break, but the replacement parts are in the same shipment as the LDO kit, so once I get the Trident back up and running it'll be printing parts for the build as I assemble things. Thankfully there's a decent amount of steps to do before I get to where I'll need printed parts, thanks to the CNC bits.

So what colours am I planning on going with? Matter3D's Matte Black ABS with Matte Orange ABS accents is what I'm going with, mainly because they're colours I rather like, and also because they make an orange I rather like the look of. Sparta3D's Bright Orange is a lovely sparkle ABS+, and Polymaker ABS is absolutely wonderful to work with, but both of them are just too yellow for my taste. A quick glance of things indicates these should work fairly well with the Chaotic Lab CNC parts that I won during a holiday giveaway.

What mods are we looking at, anyways?

- Nevermore

- Bed fans

- Lightweight Labware Kinematic Mount

- Chaotic Lab CNC parts kit

- Klicky PCB (eventually)

- Stealthburner 2 piece PCB

- VEFACH

- chamber thermistor

- Sexbolt (if needed, have one lying around anyways)

- purge bucket of some sort (seems like a nice quality of life thing, since cleaning scraps off the bottom of a v2.4 isn't as easy as a Trident)

- Sturdy handles (I like the ones my Trident has)

Might be one or two more that I forgot about putting into the list like panel clips or different hinges for the doors

^The Chaotic Lab CNC parts kit. Comes with Rev 1 feet and AB idlers, but thankfully the z motor mounts are compatible with Rev 2 feet, which I prefer the look of. Hopefully at some point a Rev 2 AB idler update will be offered. I've had a few ask my thoughts on these parts, and in all honesty, I don't know what to say. I like them, they look nice, and I hope I'll be able to have an actual opinion once I've started assembling various things.

^Quick test of how the chosen ABS colours work with the red anodizing. I'm rather certain they'll work together, doubly so because they generally won't be next to each other anyways.

Normally there'd be a pic of printed parts ready to go for the build posted here, but Foxyfluff had a wire break, but the replacement parts are in the same shipment as the LDO kit, so once I get the Trident back up and running it'll be printing parts for the build as I assemble things. Thankfully there's a decent amount of steps to do before I get to where I'll need printed parts, thanks to the CNC bits.