- Printer Model

- Voron V2.4

- Extruder Type

- Clockwork 1

- Cooling Type

- Afterburner

I have a Voron V2.4 here with a Voron Stealthburner toolhead.

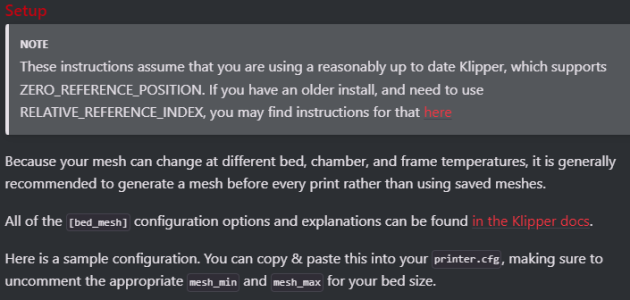

First of all, my problem is, why do you have to import the bed mesh manually, why isn't it automatic? He can do the print bed leveling on his own, so why do I have to spend time doing the mesh myself? Is there a way to generate the mesh automatically?

Regardless of the fact that calibrating the printer is more complicated than it should be, the first layer NEVER looks the same.

Sometimes it's perfect, sometimes the hot end is too close to the bed, sometimes the hot end is too far away from the bed.

I always use the same material, the same GCode and the same bed mesh. Does anyone know this problem?

Is this printer even suitable for prototyping or is it more suitable for hobbyists?

First of all, my problem is, why do you have to import the bed mesh manually, why isn't it automatic? He can do the print bed leveling on his own, so why do I have to spend time doing the mesh myself? Is there a way to generate the mesh automatically?

Regardless of the fact that calibrating the printer is more complicated than it should be, the first layer NEVER looks the same.

Sometimes it's perfect, sometimes the hot end is too close to the bed, sometimes the hot end is too far away from the bed.

I always use the same material, the same GCode and the same bed mesh. Does anyone know this problem?

Is this printer even suitable for prototyping or is it more suitable for hobbyists?