stevereno30

Active member

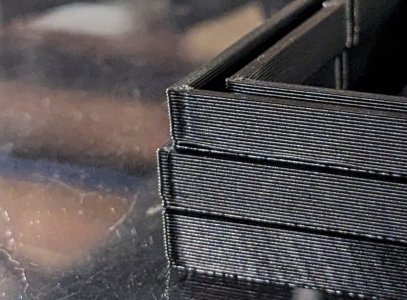

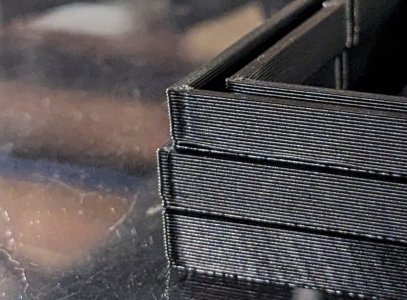

I feel like I must be missing something in Super Slicer (update: I'm not. This is apparently related to my extruder producing corner gaps at much too low PA values around 0.026) that could help prevent this issue:

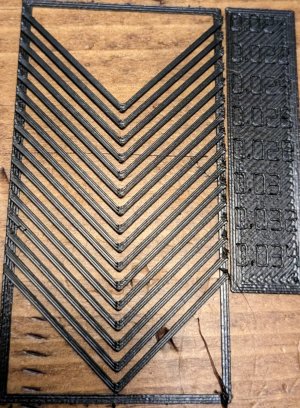

Three prints are visible in this image. 20 more are in the background, almost all with this issue. I've tried everything: lowering acceleration, lowering speed, lowering square corner velocity to zero... No matter what I do, the corners have this overshoot artefact. The only way I have been able to get rid of this is to double my pressure advance (from 0.02 up to 0.04). The problem with this is that it causes dramatic corner perimeter gaps. Prusa Slicer does a bit better job (despite having higher speeds, accelerations, etc) but I still can't get these to go away. The bottom of the stack of test prints was printed with 40mm/s perimeters and roughly 20mm/s external perimeters. It also had square corner velocity set to zero. The other two were 5 and 10 square corner velocity, and both had print speeds significantly higher, but the improvements are negligible considering how terribly slow the machine was running. The bulging is only on the trailing side of the corner, so I don't think it is PA induced bulging. Any suggestions would be greatly appreciated!

Three prints are visible in this image. 20 more are in the background, almost all with this issue. I've tried everything: lowering acceleration, lowering speed, lowering square corner velocity to zero... No matter what I do, the corners have this overshoot artefact. The only way I have been able to get rid of this is to double my pressure advance (from 0.02 up to 0.04). The problem with this is that it causes dramatic corner perimeter gaps. Prusa Slicer does a bit better job (despite having higher speeds, accelerations, etc) but I still can't get these to go away. The bottom of the stack of test prints was printed with 40mm/s perimeters and roughly 20mm/s external perimeters. It also had square corner velocity set to zero. The other two were 5 and 10 square corner velocity, and both had print speeds significantly higher, but the improvements are negligible considering how terribly slow the machine was running. The bulging is only on the trailing side of the corner, so I don't think it is PA induced bulging. Any suggestions would be greatly appreciated!

Last edited: