snow 3dp

Active member

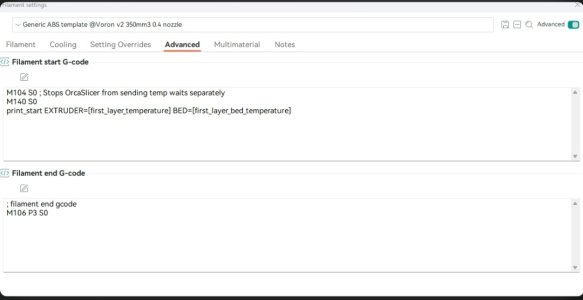

what is the issue here? i have been chasing my tail For days with start Gcode. the hotend heats to 260C from slicer settings instead of straight to 150c then it cools to 150c for tap it then homes, QGL, heaters off, QGL, home, QBL, Error

"Extrude below minimum temp

See the 'min_extrude_temp' config option for details" what would cause it to loop?

Voron 2.4 R2

Tap

Manta M8P V2

SB2209 CAN

gcode:

SAVE_GCODE_STATE NAME=STATE_G32

G90

G28

QUAD_GANTRY_LEVEL

G28

## Uncomment for for your size printer:

#--------------------------------------------------------------------

## Uncomment for 250mm build

#G0 X125 Y125 Z30 F3600

## Uncomment for 300 build

#G0 X150 Y150 Z30 F3600

## Uncomment for 350mm build

#G0 X175 Y175 Z30 F3600

#--------------------------------------------------------------------

RESTORE_GCODE_STATE NAME=STATE_G32

[gcode_macro PRINT_START]

# Use PRINT_START for the slicer starting script - please customise for your slicer of choice

gcode:

G32 ; home all axes

G90 ; absolute positioning

G1 Z20 F3000 ; move nozzle away from bed

"Extrude below minimum temp

See the 'min_extrude_temp' config option for details" what would cause it to loop?

Voron 2.4 R2

Tap

Manta M8P V2

SB2209 CAN

gcode:

SAVE_GCODE_STATE NAME=STATE_G32

G90

G28

QUAD_GANTRY_LEVEL

G28

## Uncomment for for your size printer:

#--------------------------------------------------------------------

## Uncomment for 250mm build

#G0 X125 Y125 Z30 F3600

## Uncomment for 300 build

#G0 X150 Y150 Z30 F3600

## Uncomment for 350mm build

#G0 X175 Y175 Z30 F3600

#--------------------------------------------------------------------

RESTORE_GCODE_STATE NAME=STATE_G32

[gcode_macro PRINT_START]

# Use PRINT_START for the slicer starting script - please customise for your slicer of choice

gcode:

G32 ; home all axes

G90 ; absolute positioning

G1 Z20 F3000 ; move nozzle away from bed