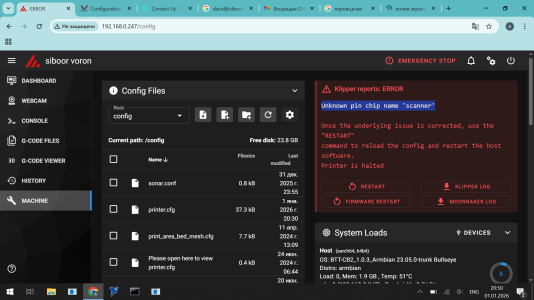

Siboor Voron 2.4r2, BTT Octopus Pro 1.0 + BTT SB2209 RP2040 + Cartographer. I've attached my printer.cfg

but the relevant sections regarding Cartographer are below.

Cartographer supposedly is already flashed but I would do it since there may be newer firmware especially

if you're using a Cartographer v3.

This is straight out of my printer.cfg, note that there's no [scanner] section. Most of the examples for the

cartographer section of the printer.cfg are outdated since they are based on an older version of Klipper.

#####################################################################

## MCU Cartographer V3 (ADXL 345)

#####################################################################

[mcu cartographer] # See

https://www.klipper3d.org/Config_Reference.html#mcu

canbus_uuid: 9168a0c3c195 ##use the one you got when setting up Katapult and Klipper.

## restart_method: command # Not needed for probes using CAN.

[cartographer]

mcu: cartographer

x_offset: 0 # This is the offset of your probe from the nozzle tip, to the center of the coil.

y_offset: 22 # This is the offset of your probe from the nozzle tip, to the center of the coil.

verbose: yes # For extra output

[adxl345]

# Select 1 of the cs_pin below depending on the probe you have.

# Having the wrong one selected will cause an Endless Bootloop

# Cartographer V4 has int2 connected to the probes PA1 pin

cs_pin: cartographer

A3 # For Cartographer V3

## cs_pin: cartographer

A0 # For Cartographer V4

spi_bus: spi1

[resonance_tester]

accel_chip: adxl345

probe_points: 175, 175, 20 # Fill out the blank with x and y coordinates where you want to run the resonance test.

[safe_z_home]

home_xy_position: 175,175 # Example home_xy_position: 175,175 - This would be for a 350 * 350mm bed.

z_hop: 10 # Z axis hop height after homing.

#####################################################################

## Z0-axis on MOTOR_2 (left front)

#####################################################################

[stepper_z]

step_pin: PF11 # Z-axis motor pulse pin

dir_pin: PG3 # Z-axis motor direction pin setting

enable_pin: !PG5 # Z-axis motor enable pin setting

rotation_distance: 40 # Active pulley circumference mm (2GT-20T pulley 40, 2GT-16T pulley 32)

gear_ratio: 80:16 # reduction ratio

microsteps: 32 # microsteps

endstop_pin: probe:z_virtual_endstop

homing_retract_dist: 0

## position_endstop is the distance of the Z limit pin trigger point from the print surface.

## Positive value = above the termination point of the platform,

## Negative value = termination point below the plateau.

## Increasing the value of position_ endstop will bring the nozzle closer to the bed.

## After running Z_ENDSTOP_CALIBRATE, position_endstop will be stored at the end of the CFG configuration.

##position_endstop: 0.5 # Modified as per actual

position_max: 340 # Maximum Z-axis print height 350mm=340

position_min: -5 # Soft Limit Minimum Stroke

homing_speed: 50 # Reset speed - maximum 20

second_homing_speed: 3 # Secondary reset speed - maximum 10

#--------------------------------------------------------------------

[tmc2209 stepper_z] # TMC2209

uart_pin: PC6 # drive communications port

interpolate: true # Whether to enable 256 microstep interpolation

run_current: 0.8 # Motor running current value(mA)

hold_current: 0.8 # holding current(mA)

sense_resistor: 0.110 # Do not change the drive sampling resistor

stealthchop_threshold: 200 # Mute threshold