m00dawg

Well-known member

I've been chasing problems for a few days now in regards to slopes that were printing great before I had to go in and mess with things  I swapped from a BMO to a Revo on my V0.2 and while I think I still have some tweaking to do, one thing I did notice was the print quality results between SuperSlicer 2.5 and 2.4 are vastly different.

I swapped from a BMO to a Revo on my V0.2 and while I think I still have some tweaking to do, one thing I did notice was the print quality results between SuperSlicer 2.5 and 2.4 are vastly different.

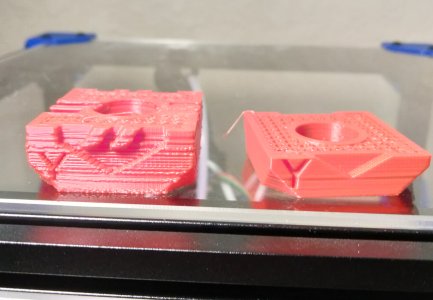

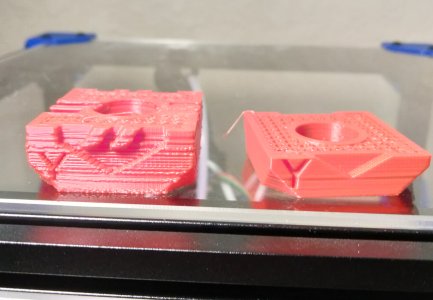

2.5 is on the left, 2.4 on the right. The photo doesn't do the results justice. The right isn't perfect but soooo much better than the left. This is the same 3MF file which is the profile I use for printing Voron parts.

Anyone have thoughts on why this might be the case? I believe the slicing mode on both is set to Classic so it's on the Arachne additions in 2.5

Trouble now is I can't seem to easily go back to 2.4. Something in my .superslicer config I suppose is jacked because if I try to click on the Cooling section under the Filaments tab is crashes. This is not trying to pass any blame on SS or anything. It's Open Source and aside from small donations to the maintainer, it's "Free" so hard to complain about that. I'm just trying to get to the bottom of what's going on is all.

2.5 is on the left, 2.4 on the right. The photo doesn't do the results justice. The right isn't perfect but soooo much better than the left. This is the same 3MF file which is the profile I use for printing Voron parts.

Anyone have thoughts on why this might be the case? I believe the slicing mode on both is set to Classic so it's on the Arachne additions in 2.5

Trouble now is I can't seem to easily go back to 2.4. Something in my .superslicer config I suppose is jacked because if I try to click on the Cooling section under the Filaments tab is crashes. This is not trying to pass any blame on SS or anything. It's Open Source and aside from small donations to the maintainer, it's "Free" so hard to complain about that. I'm just trying to get to the bottom of what's going on is all.