Nordlicht77

Active member

- Printer Model

- Voron R2 350mm

- Extruder Type

- Orbiter

- Cooling Type

- Stealthburner

Hello

I am a new owner of a Voron R2 350mm

I have the following components

Voron 2.4 Metal Parts

CHAOTICLAB CNC Voron Tap

Stealthburner

BIGTREETECH EBB SB2209

Octopus Pro H723

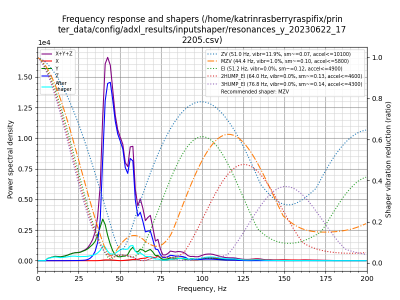

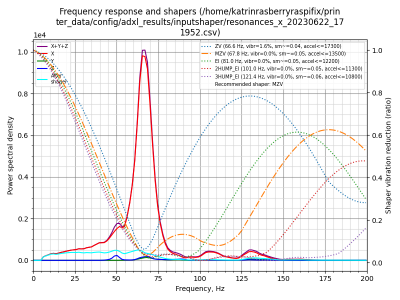

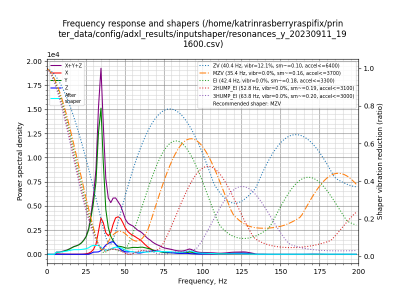

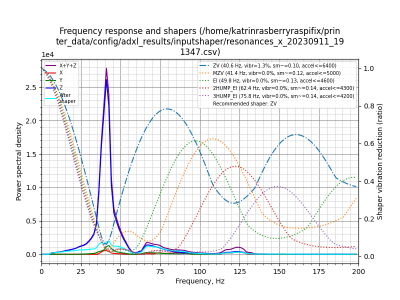

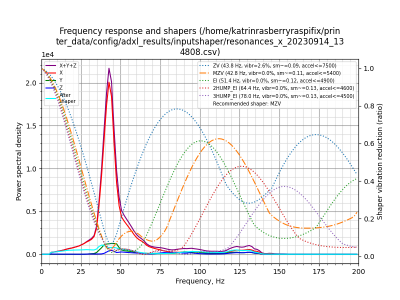

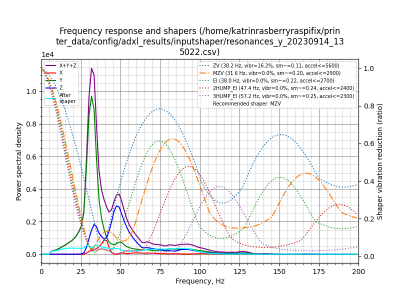

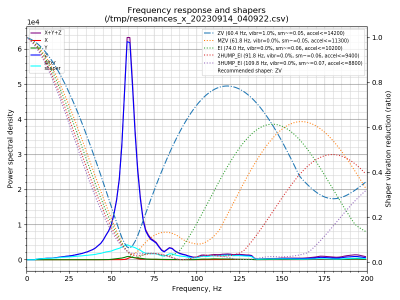

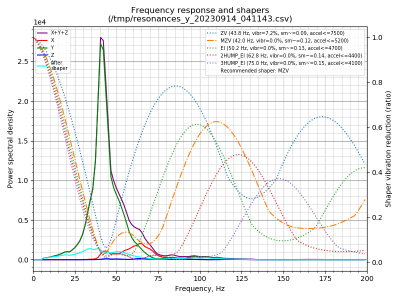

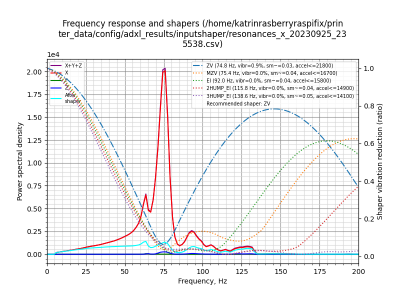

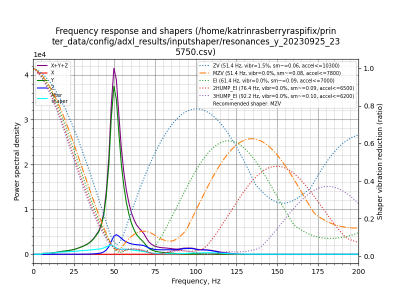

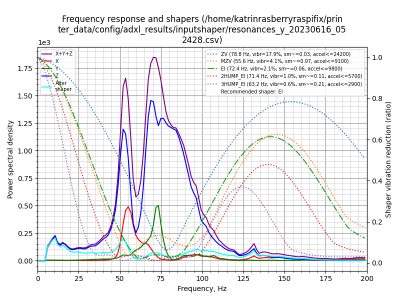

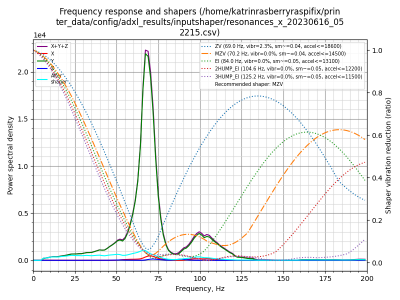

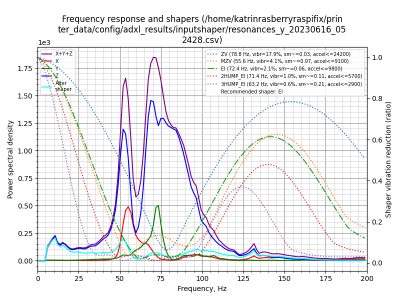

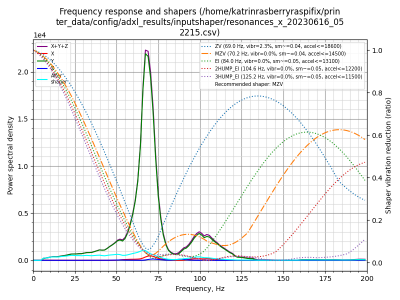

I'm having a little trouble understanding the Input Shaper Result correctly

Have watched this video

Can you give me a hint what else could be or is it alright

Greet

Nordlicht

I am a new owner of a Voron R2 350mm

I have the following components

Voron 2.4 Metal Parts

CHAOTICLAB CNC Voron Tap

Stealthburner

BIGTREETECH EBB SB2209

Octopus Pro H723

I'm having a little trouble understanding the Input Shaper Result correctly

Have watched this video

Can you give me a hint what else could be or is it alright

Greet

Nordlicht