ChrisA

Well-known member

Introduction.

My current printer is an Anet A6 bought as a kit in perhaps 2016. It is an i3 clone with a laser cut acrylic frame. The first thing I did was print some braces to reinforce the frame and then I printed more that allow the printer to be screwed down to a workbench. With the printer firmly now part of a built-in bench it does not move at all and does acceptable work in PLA. My interest in 3D printing comes from my "real" interest in robotics. I am working on version 2.0 of a small quadruped "dog" robot.

Professionally I worked as an engineer in the defense aerospace industry here in Southern California, doing mostly software although I have some formal education in electrical engineering. But mostly I wrote software related to missiles, radars, rockets, and communications. I was able to retire early and had a short second career teaching high school science. Now I am really retired. I have time to work on these printers while trying to ride a road bicycle 100+ miles a week (that's the goal) and spend at least four weeks on the trail in the Serrias (that's the goal.)

My initial plan was to build a V2.4 but I want it customized to print at least two materials. That means IDEX, ERCF or the new "Tap Changer". All of these are not yet 100% mature and I also want a smaller printer that does not take 40 minutes to come up to temperature and will fit on my desk. 120 mm cubed is enough space to make most of my robot parts and also all of the Voron v2.4 parts. I will use the V0 to build a customized V2 next year.

There are already so many of these build logs online. So why do one more? I hope to address things that others don't

Log, Feb 7, 2024

I have two boxes of parts from Formbot. The parts are all of excellent quality. I see no reason to spend more on some other reseller's kit.

1) Electronics are the BTT Pi3 cone and a "pico" MCU board. Both seem well matched to a V0 printer. There is a small V0 display which is good enough as a status display and for very occasional use. It looks and works just like the one in my Anet A6 printer. I almost never use it. I would get one of the larger touch-screen displays if I planned to use the directly attached screen.

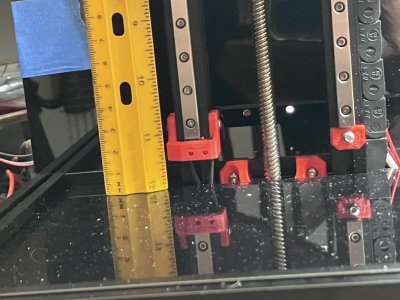

2) The mechanical kit uses Moon's motors and a good quality Chinese linear stainless steel rail. One is a Z1 preloaded for use on X axis. It is easy to tell it from the non-preloaded rails. There were oiled but I need to grease them. I think you'd have to spend a lot to get slightly better rails.

3) Formbot claims to use ABS-GL filament (ABS with 10% chopped glass fiber) in their printed parts. Yes, their parts are different and, I think better. The plastic is a dull sheen and sparkles in the light. layer lines are visible only if you look close, dimensions seem to be spot-on. They look better than many photos of self-printed parted I've seen online. They are also more rigid than plain ABS. For $60 you get a lot of parts. After this V0 is built it will be a challenge to tune my printer to make parts this nice. The cosmetics of these parts are "mat with sparkles" and not the shiny semi-gloss of other ABS parts. As a quiet statement, not to complain about tiny imperfections they include a full sheet of #500 wet/dry sandpaper. The parts fit with no sanding but all 3D-printed parts can be improved with sanding. There are some rough areas that are hard to see but can be found with my finger. Sanding will remove these.

4) panels are all 3mm clear PC or slightly thicker aluminum composite. This is an upgrade from the black PC. At least I think it might be.

STATUS, What is built...

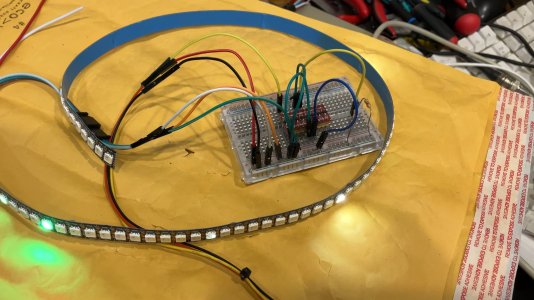

I am doing this backward. Most people leave wiring and software setup until the end but I started there. I have the Meanwell power supply AC mains power cable and switch and the Pi3 clone and MCU and display all screwed down on a pine board and running. Klipper is running and mainsail and octopi. I was able to upgrade the OS on the Pi to Debian "Bookworm". The heaters are left disconnected. I tried running a print using the Mainsail interface but it failed because Klipper noticed the heater temperature was not moving. Next, I will install a webcam and experiment with other kinds of cameras.

What I have learned so far.

1) The BTT Pi3 clone is well suited for its intended use case and has connecters the standard Pi lacks. But I can't get a "standard" version of Ubuntu Linux to boot. BTT's image loads on the SD card and boots but that image is based on the older "Bullseye" Debian. I was able to upgrade in place to Bookworm. I suspect I could get Ubuntu to work if I made a custom kernel with whatever mods BTT did. I have not looked into it yet. But it seems this is NOT is perfect Pi3 clone. It works and maybe even works better than a real Pi3. It's running Bookword as I type with Klipper, Mainsail Fluid and Octopi all installed. about 8GB of the 16GBSD card are used. The Pi3 has 1GB of RAM and about half is used with everything I installed running at the same time.

2) The content and quality of these kits change fast with time. If you see a 6-month-old YouTuber doing an unboxing of a kit, you can ignore it as "outdated". Most of what I found in this kit differed from what I saw on YouTube and that was a Good Thing.

3) It used to be that if you ordered an upgraded hot end from Formbot they would upcharge you for it and send it in a separate smaller package. So you would end up with two hot-ends, the default V6 and whichever upgrade you paid for. But now they place the upgrade in the main box and remove the V6, so you end up with only one hot end. They also were able to reduce the price of the upgrade. I paid $40 for a Pheatius Dragon Standard Flow.

I have photos and will post a few "soon".