Post-holiday progress pics

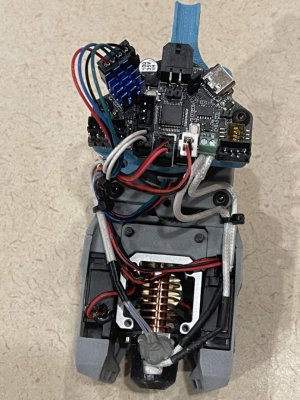

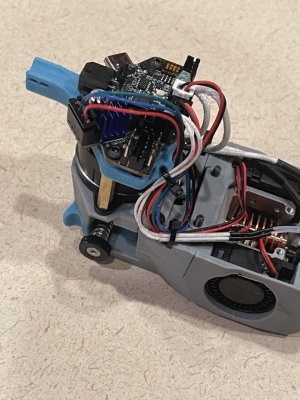

Got the towhead put together, this is a stealth burner of course

I ran into an issue with the DropEffect XG hotted though, the thermistor is secured in a little brass support with some form of ceramic compound, but mine completely disintegrated. I saw a bunch of bare copper wire in mine as well, so I replaced it with a regular glass bead thermistor I had handy, and used a bunch of high-temp JB-Weld to attempt to hold it in place. This didn't work, as soon as I was done with this photo and went to mount the toolhead it popped out of the brass retainer

I'm trying a different approach now, will know in another 24 hours or so if it holds, if not then I have to keep looking for ways to get this to work. I'd just order a replacement part for this, but can't find anything other than full hotend packages, and not going to do that when all I need is a new thermistor assembly

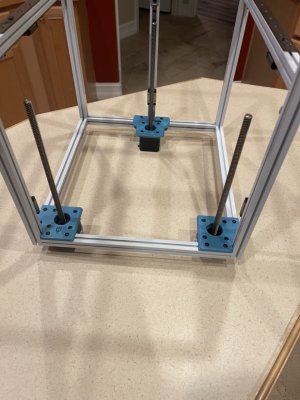

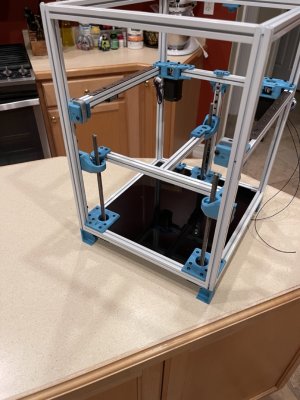

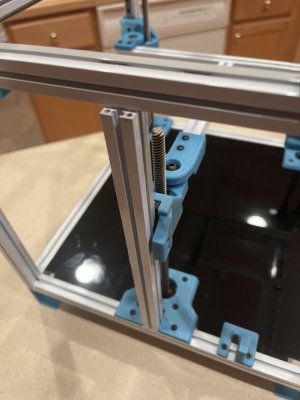

In other news, the printer is fully belted, de-racked, and looking good, just waiting on the toolhead, then it's bed install and wiring time!