stevereno30

Active member

- Printer Model

- Voron 2.4 350mm

- Extruder Type

- Galileo

- Cooling Type

- Stealthburner

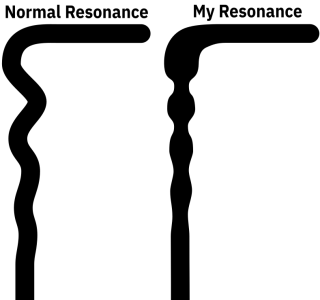

I have a 350 V2 with a seemingly impossible-to-solve bit of ghosting. It is immune to input shaping, doesn't seem to be related to the toolhead, and only appears on y-movements (meaning, I assume, the X axis is its origin). It is more pronounced when the toolhead is moving backwards toward y-max, but it also appears during movements toward y-min as well.

Some info on my Formbot kit circa 2021 machine:

All prints were printed with accel set to 1500 and speed set to 52 unless the tuning tower demanded different settings.

Some info on my Formbot kit circa 2021 machine:

- X axis rail is a CPC MGN12 equivalent with high preload

- Y axis rails are TRVIS MGN9 equivalents with medium preload.

- Y rails have backers (Formbot MGN9 rails)

- Vitali CNC Tap with high preload TRVIS MGN9

- I am running Nitehawk as umbilical

- Toolhead is a Stealthburner with Galileo 2

- Hotend is a Dragon or a V6 or an X1c (these were printed with the X1c, though all perform the same in these tests)

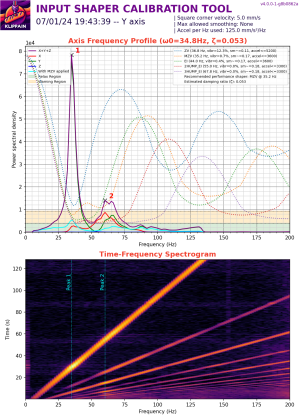

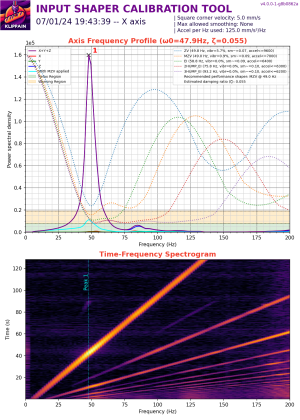

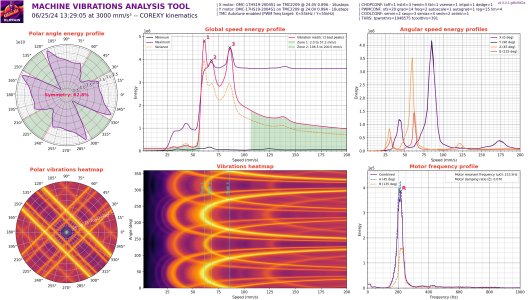

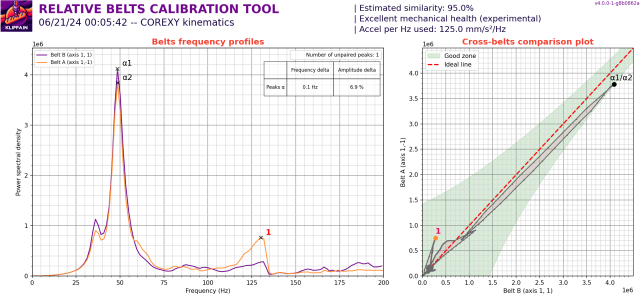

- ADXL graphs look good (see below)

- Gantry idlers and pulleys are genuine Gates, as are the belts

- Gantry bearings are BOM RainDew parts

- Pins mod on all gantry parts

- Front idlers are VoronBFI

- Printing with 2hump_ei at 60hz, 50hz, and 40hz per Klipper guide

- Swapping Tap for a stock V2 X carriage

- Cleaning rails thoroughly and greasing with EP2

- Swapping all gantry rails for ones with lower preload

- Swapping A/B motors (using BOM OMCs currently, but also tried Moons')

- Changing belts

- Changing front idlers

All prints were printed with accel set to 1500 and speed set to 52 unless the tuning tower demanded different settings.

Last edited: