stevereno30

Active member

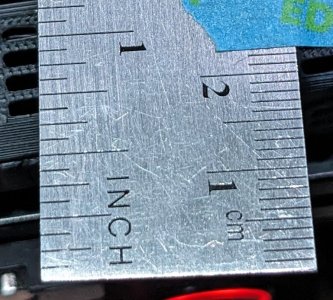

Does anyone know what could be preventing my Dragon hot end from extruding to its potential? Printing with ABS, I get significant die swell and my Galileo2 can only push 93 of the requested 100mm when extruding into open air at 10 mm³/s. Brand new nozzles don't help, and it still cannot push the full 100mm when printing 20°C above the ABS' max print temp. Without a hotend mounted, my extruder pushes exactly 100mm when I ask for 100mm. My machine is a time vampire with so many inexplicable issues, so I'm trying to knock out the issues that *should* have easy explanations. Any help is appreciated!