- Printer Model

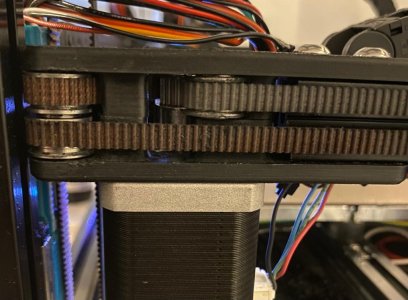

- V2.4 R2

- Extruder Type

- Clockwork 2

- Cooling Type

- Stealthburner

Hello everyone, my name is kevin and i am 28 years old.

i'm from germany and i apologize for my bad grammar. I recently got a Voron 2.4 R2.

Unfortunately I have a problem which I can not assign and hope that maybe someone can help me here.

Thank you and best regards

Look at de Videolink

i'm from germany and i apologize for my bad grammar. I recently got a Voron 2.4 R2.

Unfortunately I have a problem which I can not assign and hope that maybe someone can help me here.

Thank you and best regards

Look at de Videolink