m00dawg

Well-known member

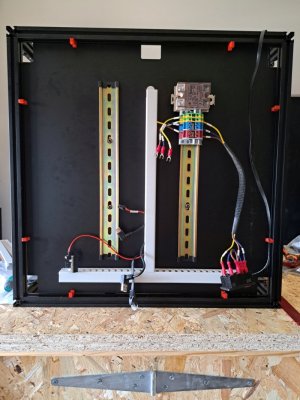

I have the 2.4 LDO kit and noticed that the build notes list installing the deck supports on page 29 of the manual (that's the page where you install the DIN rails). I searched through the manual on where those otherwise are installed but can't seem to find it? The supports are part of the Voron 2 Repo and do not seem to be an LDO specific part?

I tried to figure out how they might be installed, felt kinda silly as I didn't figure it out. I'm hoping I can install them after so I can proceed with the build (I'm on page 52, the print bed).

But yeah anyone have any thoughts or suggestions?

I tried to figure out how they might be installed, felt kinda silly as I didn't figure it out. I'm hoping I can install them after so I can proceed with the build (I'm on page 52, the print bed).

But yeah anyone have any thoughts or suggestions?