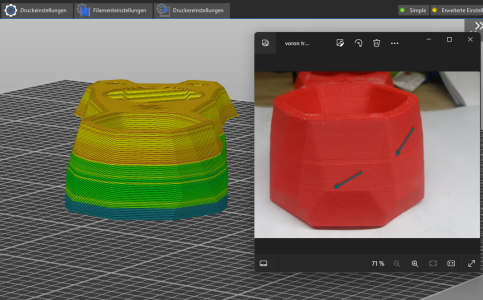

It's a shame that I have a printer that I haven't been able to print properly with until now

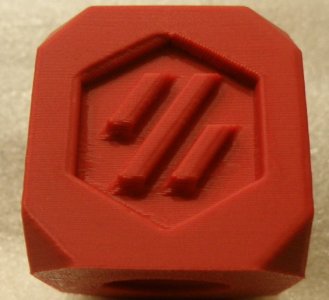

I have now checked the belts again with this tool

Voron Stuff. Contribute to Diyshift/3D-Printer development by creating an account on GitHub.

github.com

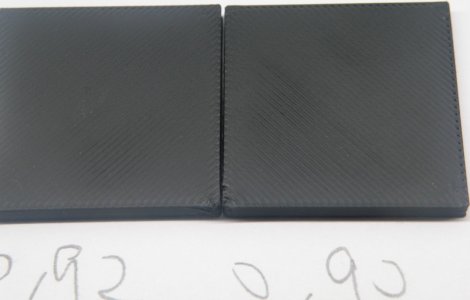

Then I put a second aluminum plate on top of the other aluminum plate on the bed

To see how you can see that the cubes are almost always at the same height.

Unfortunately it is also at altitude so you can assume that the Z motors and belts and pulleys are not the culprits

I'm currently printing with the Prusa profile reset, the extrusion multiplier from 100-80

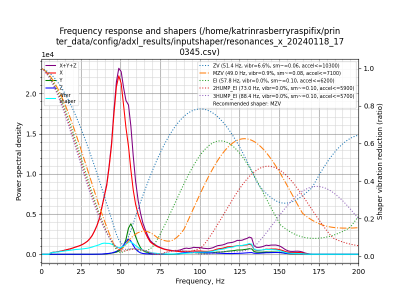

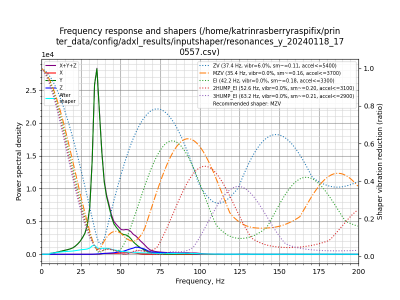

The input shaper can't be the culprit

1.I have now checked all pulleys

2.I changed all the belts

3. I replaced all ruler rails except x

4. I swapped the A/B and Z motors

5 I checked all the screws

6.Changed the extruder

7.I tried Prusa, Superslicer, Cura, Orbit

8.Gantry Squaring

9.Extruder Calibration

10.First Layer Squish

11.Linear Advance Pattern Method

12. I'm currently making the Extrusion Multiplier 100-80

13.Retraction

14.Determining Maximum Volumetric Flow Rate

15.Input Shapers

16.VIBRATIONS_CALIBRATION

Then I don't know what to do next