BallisticTech

Active member

V0.2 - Formbot Kit Build

Part 1 - Unboxing and cPIF Parts

Unboxed the Kit on my live stream last night - https://youtube.com/live/qOcGWsB79Wo

Full Review

**NOTE** - My Github Repo with a bunch of resources for the Formbot V0 Kit: https://github.com/SrgntBallistic/Formbot-V0

Since there's a general lack of documentation for this kit I've tried to compile everything I can that will help others have an easy time building the kit.

I hope to update the build log with subsequent stream VoDs, videos, and text updates on how it went if it proves to be of interest to others.

Full disclosure the kit was provided by Formbot for making content. I paid for shipping

I'll be building the kit as "stock" as possible and will not any issues I have in the process. I've bought a full extra hardware kit from Sparta3D so if any hardware is missing I can keep going. Same for fans and other things I've noted can have issues in other folks builds.

Fairly happy with the kit contents so far(not having built one before):

-$349 Starting Price

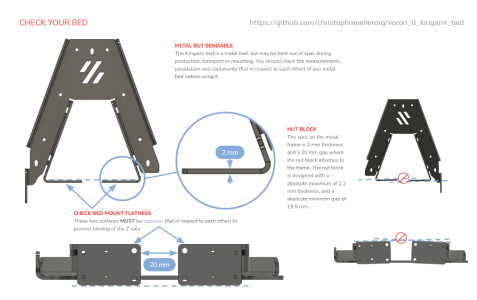

-Kirigami Bed Frame (Not full kit, no RGB LED, pcbs or wagos)

-BTT Pi V1.2 (Only V0 kit I know of with a default Pi alternative included...?)

-BTT SKR Pic

-CHC V6 Hotend (Upgradeable to Dragon/HF)

-Double Sided PEI Sheet

-Crimped Wiring Looms

-Moons Motors

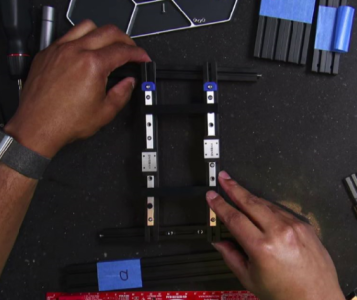

-Stainless Steel Rails

-MIC6 Cast Aluminum Build Plate

-Polycarbonate Panels

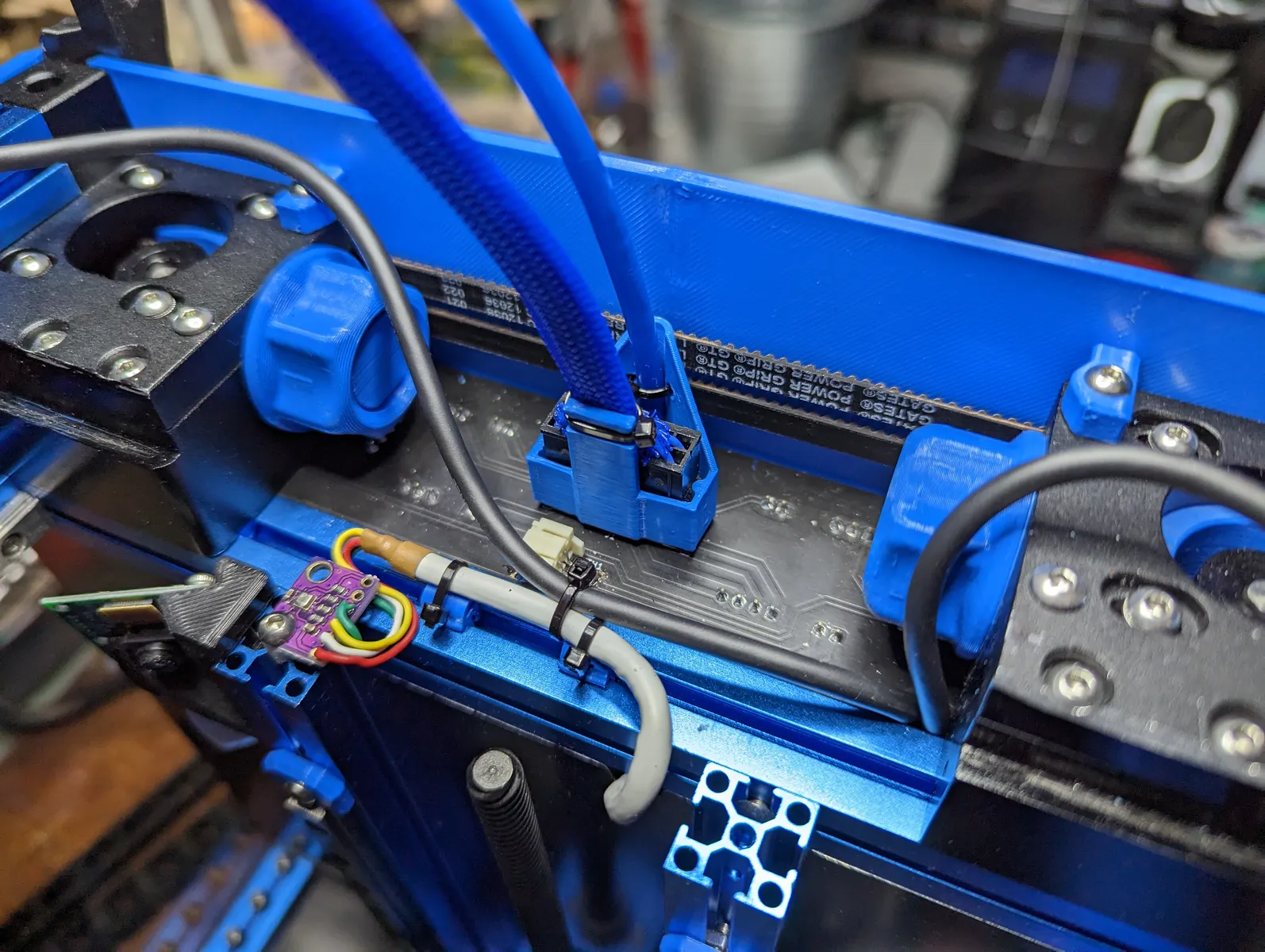

-Gates Belts

-Vivedino 60W Silicone Bed Heater

-Stainless Steel Hardware

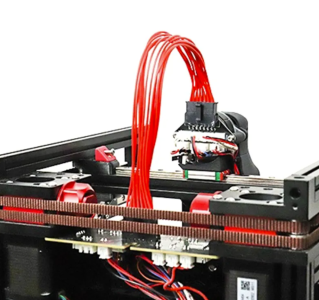

-Umbilical Board + Harness

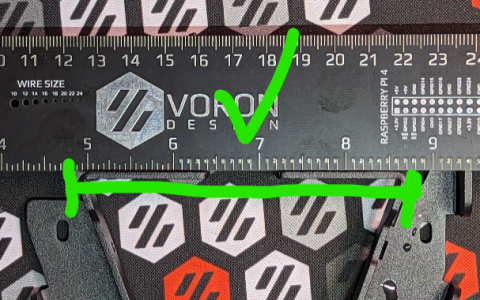

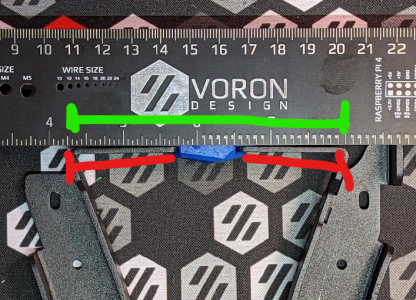

-Makerbeam XL Extrusion (These are not Makerbeam XL extrusions as noted in the Formbot listing. They are more like LDO style profile)

-Meanwell 150W PSU

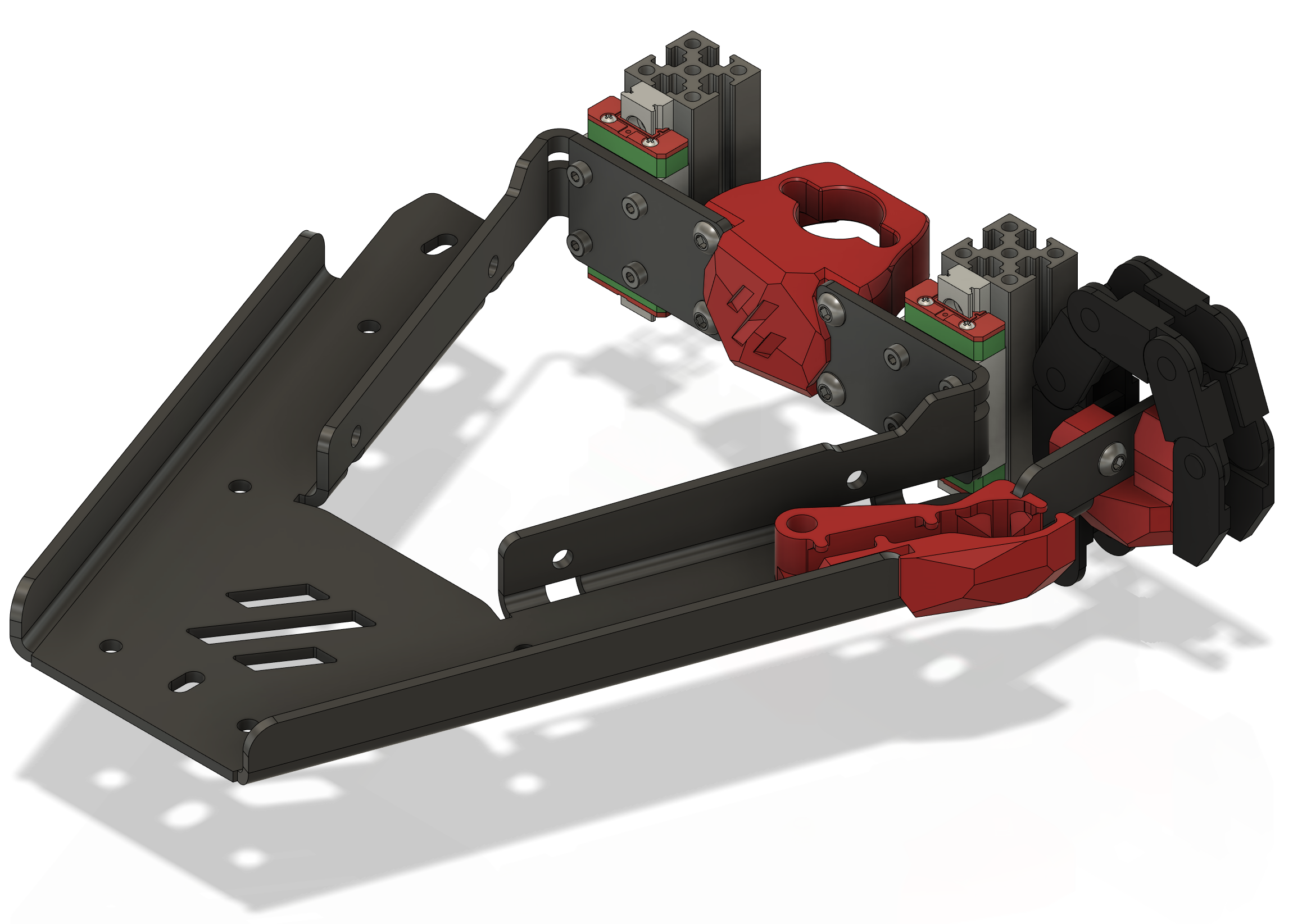

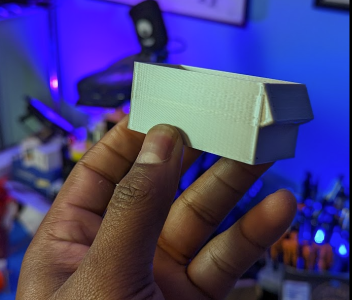

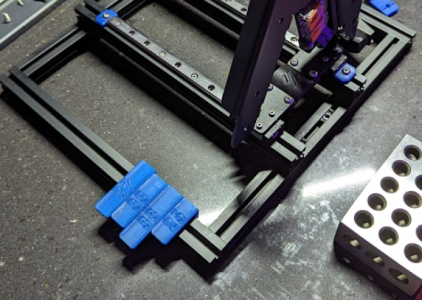

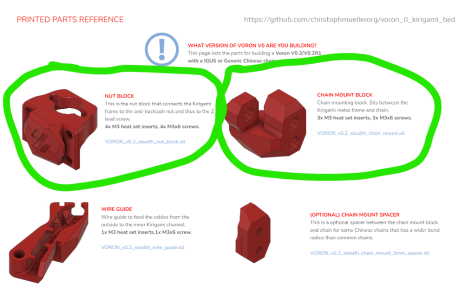

cPIF Parts from Fabreeko came and are looking pretty nice. Thanks Will

If you have any specific questions about the kit LMK

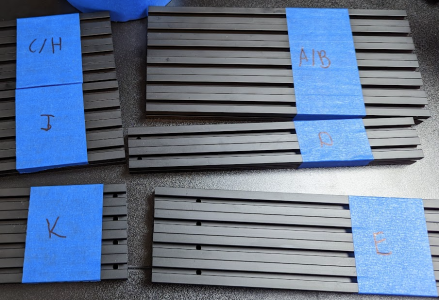

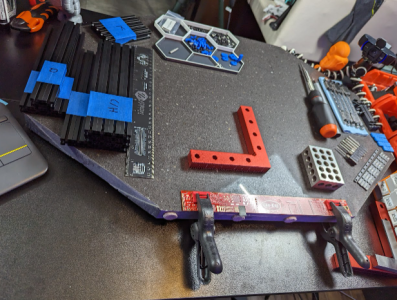

Unboxed kit organized

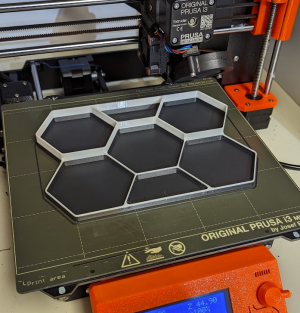

I'll probably print up some small parts organizers or dividers for this parts bin so I don't have to fish hardware out of the bags.

I got a nice remnant from a friends kitchen renovation for building the frame

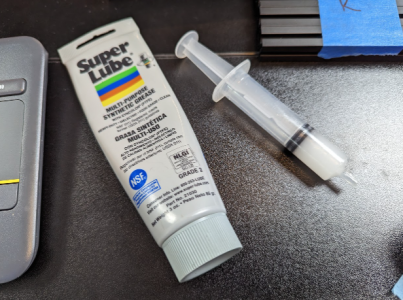

I think in Part 2 I'll cover prepping for the build. More organization, Frame Extrusion Identification, Rail Cleaning & Lubing, and Printed Part Cleanup.

Cheers

Part 1 - Unboxing and cPIF Parts

Unboxed the Kit on my live stream last night - https://youtube.com/live/qOcGWsB79Wo

Full Review

**NOTE** - My Github Repo with a bunch of resources for the Formbot V0 Kit: https://github.com/SrgntBallistic/Formbot-V0

Since there's a general lack of documentation for this kit I've tried to compile everything I can that will help others have an easy time building the kit.

I hope to update the build log with subsequent stream VoDs, videos, and text updates on how it went if it proves to be of interest to others.

Full disclosure the kit was provided by Formbot for making content. I paid for shipping

I'll be building the kit as "stock" as possible and will not any issues I have in the process. I've bought a full extra hardware kit from Sparta3D so if any hardware is missing I can keep going. Same for fans and other things I've noted can have issues in other folks builds.

Fairly happy with the kit contents so far(not having built one before):

-$349 Starting Price

-Kirigami Bed Frame (Not full kit, no RGB LED, pcbs or wagos)

-BTT Pi V1.2 (Only V0 kit I know of with a default Pi alternative included...?)

-BTT SKR Pic

-CHC V6 Hotend (Upgradeable to Dragon/HF)

-Double Sided PEI Sheet

-Crimped Wiring Looms

-Moons Motors

-Stainless Steel Rails

-MIC6 Cast Aluminum Build Plate

-Polycarbonate Panels

-Gates Belts

-Vivedino 60W Silicone Bed Heater

-Stainless Steel Hardware

-Umbilical Board + Harness

-

-Meanwell 150W PSU

cPIF Parts from Fabreeko came and are looking pretty nice. Thanks Will

If you have any specific questions about the kit LMK

Unboxed kit organized

I'll probably print up some small parts organizers or dividers for this parts bin so I don't have to fish hardware out of the bags.

I got a nice remnant from a friends kitchen renovation for building the frame

I think in Part 2 I'll cover prepping for the build. More organization, Frame Extrusion Identification, Rail Cleaning & Lubing, and Printed Part Cleanup.

Cheers

Last edited: