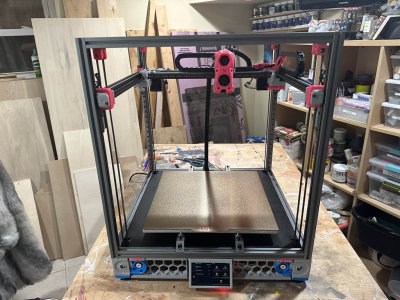

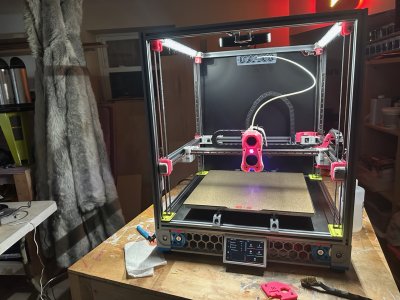

Rough weekend of highs and lows in the basement

First, did some software tweaking to get my LEDS to indicate status; struggled for a minute to figure out why my code wasnt firing and had a breakthrough while down the street at a cookout- realized I was trying to call in the place I was defining, and moved the code. no errors! but in my attempt to verify remotely, I crashed into a benchy still on the bed which must have knocked the wire I had a short in lose and my constant MCU disconnects returned.

so buckled down and resolved to get my CAN BUS installed. (the kit arrived earlier this week, but was putting it off as I wasnt eager to rip apart my print head and deal with the super tiny connectors.

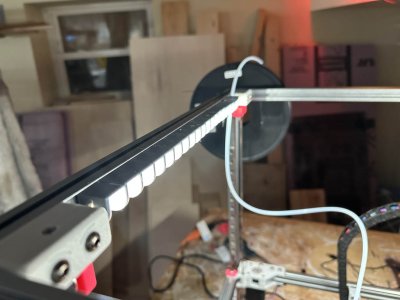

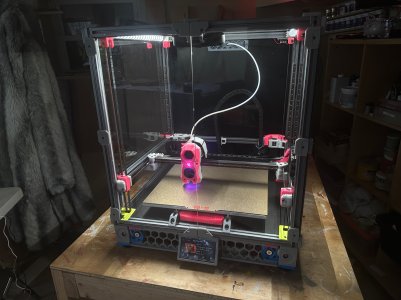

anyhow, print head disassembly.

at first it went great. the smaller breakout board uses Dupont connectors, which I can crimp easily . in fact, the wire management is much nicer than before, with everything now the perfect length with no slack having to be taped up to stay out of the way. awesome!

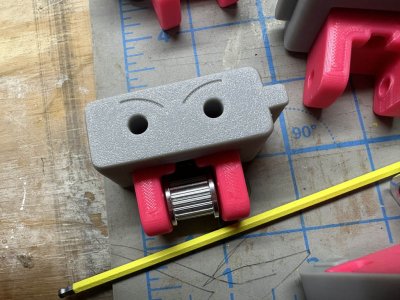

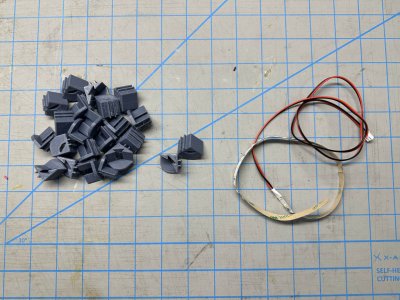

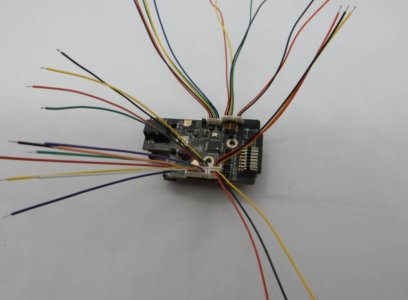

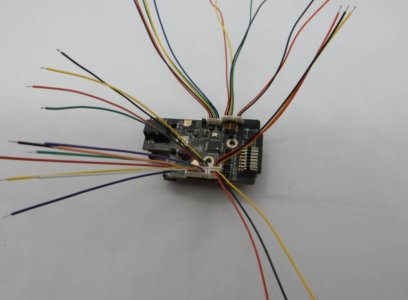

I did not take any photos of the main breakout board assembly because it was such a PITA. Tiny connectors are in fact TINY. here is a product shot that probably doesn't accurately communicate jsut how freaking tiny these freakers are.

but I did it!

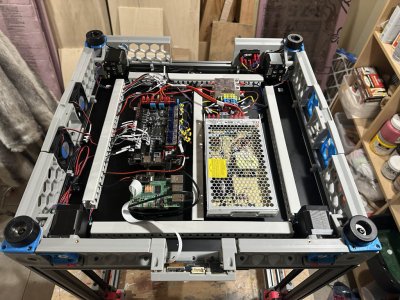

onto configuring the U2C and installing Can.

Can breakout board- flashed firmware fine!

Can control board- flashed firmware fine!

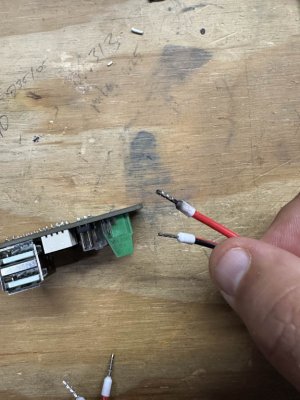

Can umbillacle cable- built correct wiring harness, tested it with multimeter, verified pin out- awesome!

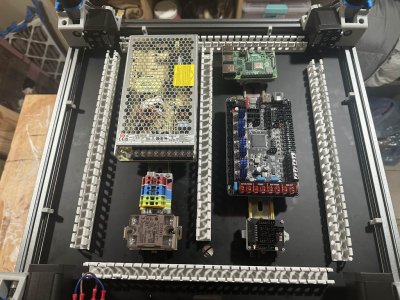

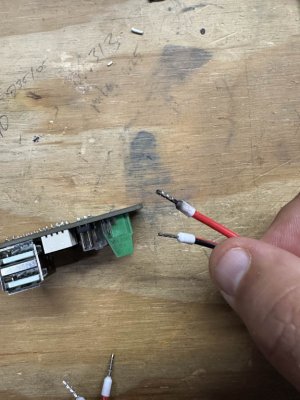

time to plug it all together. at this point it's 5am and I am still riding my high from successfully managinb all the fiddly connectors and getting that resembled and flashing all my firmware right. I need to connect the Can control board to my power supply, but dont see any examples in any of the video reviews, nor documentation. I think I have a bright idea and wire it in to the open slots of the UK2.5b power distribution block.. (cue curbyourenthusiasm music)

turns out that was real dumb. First ground and earth? not the same thing. not the same thing at all. Also, that red block is connected to my mains, not the 24v, so

yeah, loud pop, big flash and blue smoke

Electrical engineer on discord chastises me and tells me to throw that board away immediately. I declined to tell them about the second pop I heard, but I assume that was on the breakout board that was also connected in that power chain , so throwing that away too.

Fedex replacement for all the can bus ordered. hopefully it's just a $75 mistake that sets me back 2 days.

oh, and while this was happening, I was printing a new SB Mount on my ender and I hadn't heard anything from it in a few and I look over and its just a giant melted blob of ABS covering the whole hot end. Rather than deal with it, I jsut walked away from the bench in disgust and went to bed defeated at 5:30 am,

but man, the can bus conversion gave my crimper collection a workout.

...

last night I at least tried to get the ender back online, but the hot end was in a real rough state. replacement hot tend ordered :/

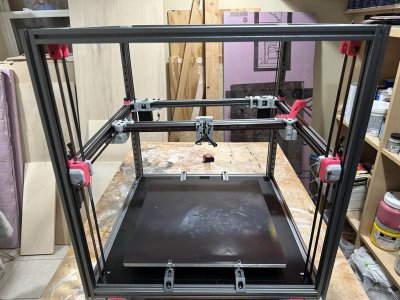

so yeah, current status: two busted printers,

and my little voron 0.2 kit was just delivered this morning. lol/doh.

ideally big voron is an easy fix- fingers crossed it's simply a matter of flashing firmware on replacement boards and dropping them in place and connecting power in the proper place. that stuff is going out on a Fedex truck today for delivery tommorow.