Samppa.D78

Member

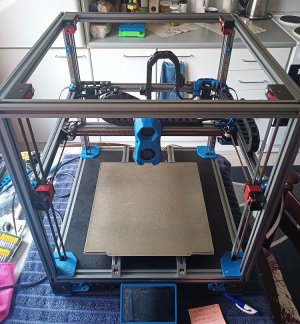

- Printer Model

- Voron 2.4r2

- Extruder Type

- Clockwork 2

- Cooling Type

- Stealthburner

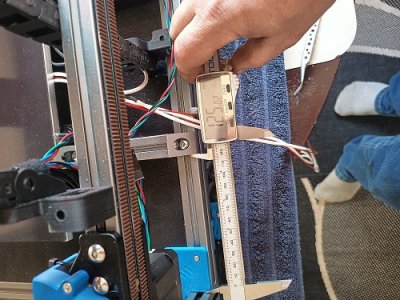

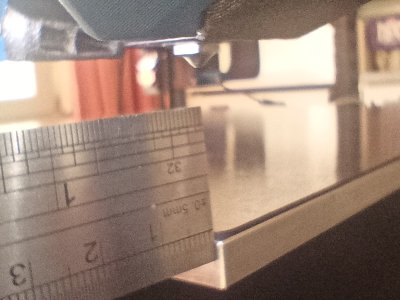

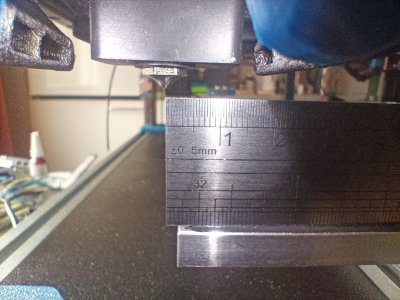

Hi. I was running final check on the motion system and when checking 0.0 position found out that tool head nozzle comes short of the bed corner by 10mm in Y direction when it is at 0.0 position. I would expect that when tool head is moved to left front corner of the bed nozzle would be at the left front corner over the bed. This is not the case. Bed size is 300x300 and bed was assembled as per voron manual. I have confirmed bed and extrusions position is correct. In Y direction when homed i have about 10mm of free space available to move bed and endstop back,so do i just move my bed and z endstop back and configure new position in klipper? I also have about 10mm of possible travel after 0.0 position is triggered so option 2 set max travel distance to 310? What would be the best solution?