erik.zweigle

Member

- Printer Model

- V0

- Extruder Type

- Orbiter

- Cooling Type

- Other

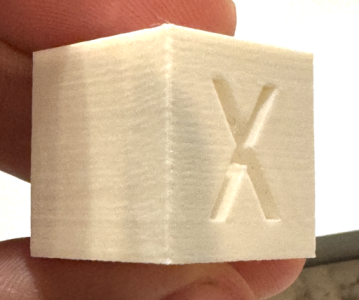

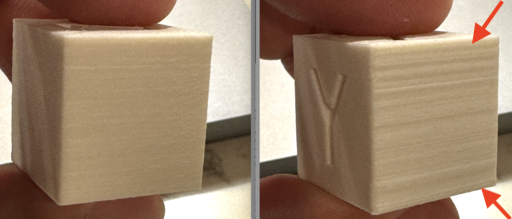

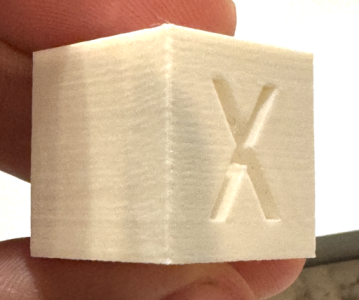

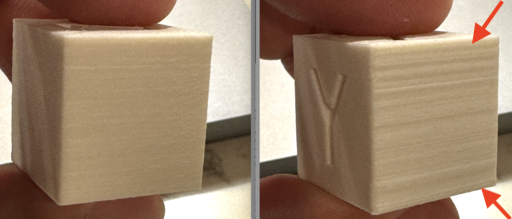

Hello, I get exaggerated Z-banding on a single wall as shown below with this 20 mm test cube. The face with the "Y" is fine, and opposite to "Y" is fine. The face with the "X" is fine, but the face opposite to "X" has these uneven steps. I've tried slicing with various features adjusted:

OrcaSlicer

- precise wall on/off

- fan speed 60% always vs adjusting

- slow printer down for better layer cooling

- accel_to_decel on/off

I've ran the Klipper recommended skew calibration for X & Y. There was only a difference of 141.1 vs 140.8 in the skew test but enabling skew vs not made no difference.

The wall opposite to this issue has the "X" and I don't see the same Z-bands on it so I didn't think it was a belt issue. However, I did reuse the same belts when I removed my X-carriage during a change to a new toolhead and it was tricky to get the belts pulled through their slots again. Without additional belt to grab hold of and pull I ended up pulling one side through by 4 teeth and then just clamping the other side in with the maker beam nuts retaining them. Would unequal belt tension left/right cause this single wall Z-band? Has anyone encountered a similar issue or recognize the problem?

OrcaSlicer

- precise wall on/off

- fan speed 60% always vs adjusting

- slow printer down for better layer cooling

- accel_to_decel on/off

I've ran the Klipper recommended skew calibration for X & Y. There was only a difference of 141.1 vs 140.8 in the skew test but enabling skew vs not made no difference.

The wall opposite to this issue has the "X" and I don't see the same Z-bands on it so I didn't think it was a belt issue. However, I did reuse the same belts when I removed my X-carriage during a change to a new toolhead and it was tricky to get the belts pulled through their slots again. Without additional belt to grab hold of and pull I ended up pulling one side through by 4 teeth and then just clamping the other side in with the maker beam nuts retaining them. Would unequal belt tension left/right cause this single wall Z-band? Has anyone encountered a similar issue or recognize the problem?