- Printer Model

- V2.4R2

Hi all,

I'm building a V2.4 R2 and having some problems with the Z belts.

I got all 4 Z belts installed and tried to tension them to 140Hz, the problem I'm having is that the belt part that goes from the gantry to the lower pulley stays lose.

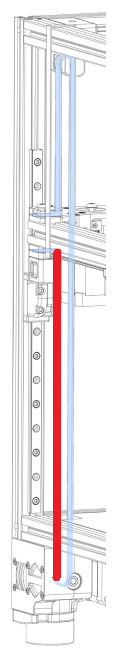

On the picture I marked the belt part red.

I raised the tension to 200Hz but that doesn't help, the lower parts stay lose.

Since it happens on all 4 belts it must be me doing something wrong, any advise/tips?

I'm building a V2.4 R2 and having some problems with the Z belts.

I got all 4 Z belts installed and tried to tension them to 140Hz, the problem I'm having is that the belt part that goes from the gantry to the lower pulley stays lose.

On the picture I marked the belt part red.

I raised the tension to 200Hz but that doesn't help, the lower parts stay lose.

Since it happens on all 4 belts it must be me doing something wrong, any advise/tips?