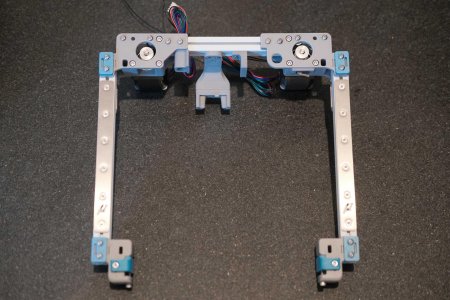

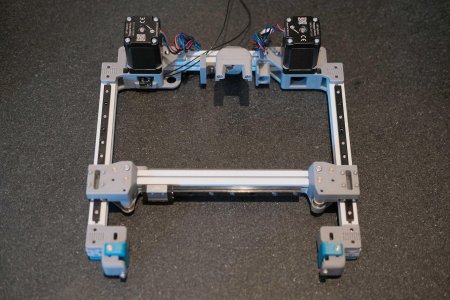

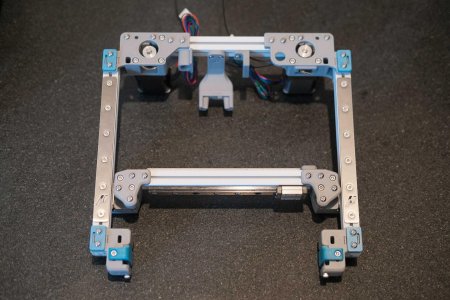

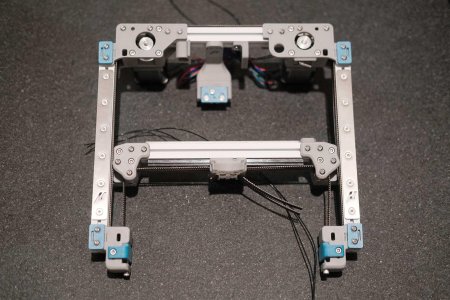

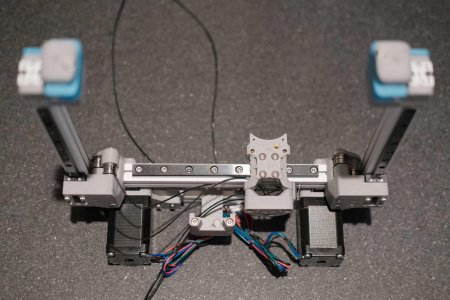

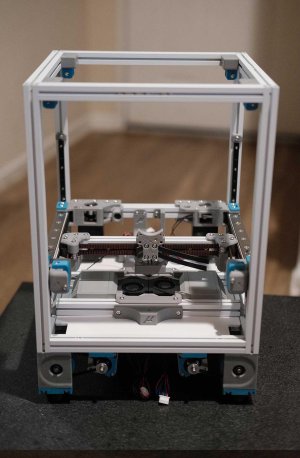

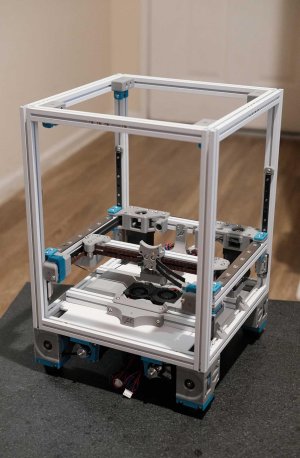

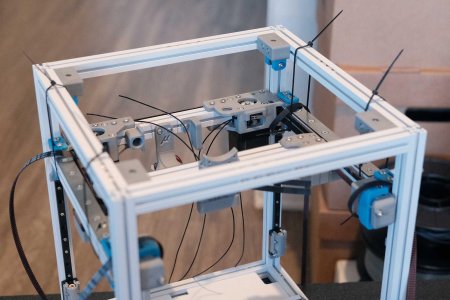

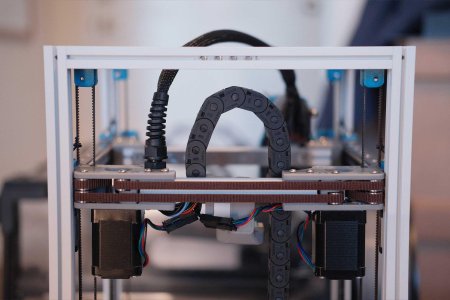

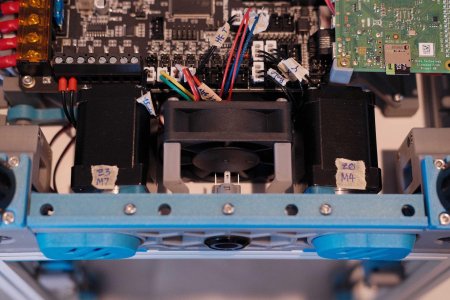

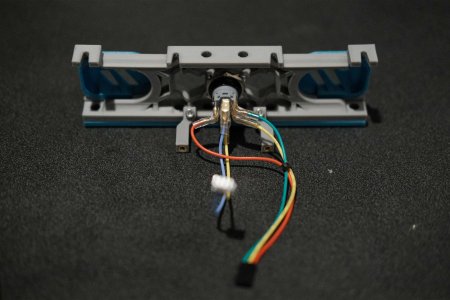

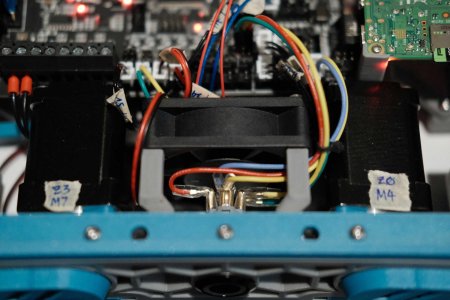

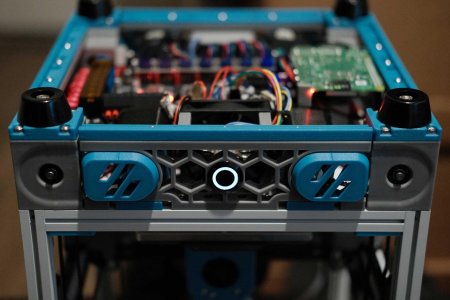

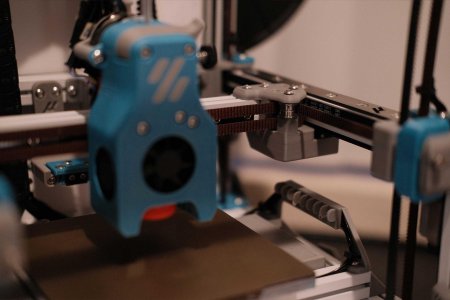

Gantry - Mounting A/B Idlers & Drives

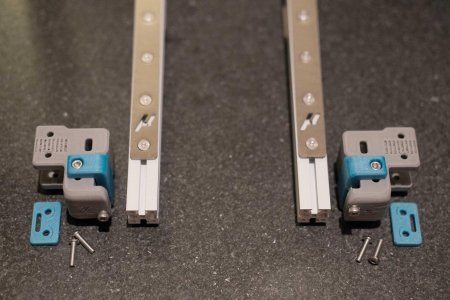

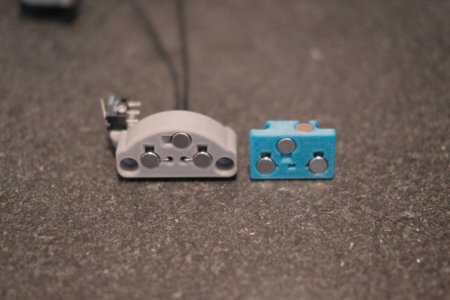

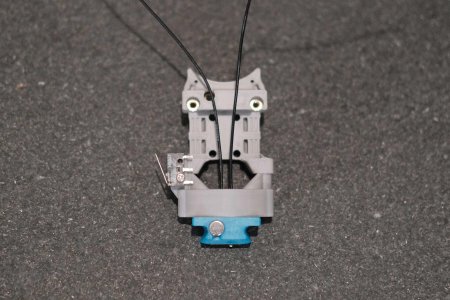

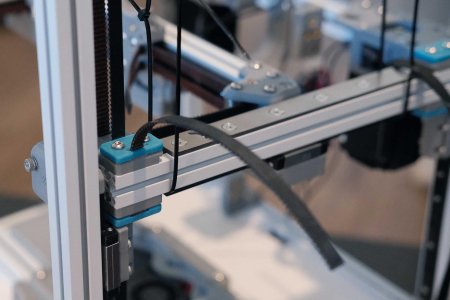

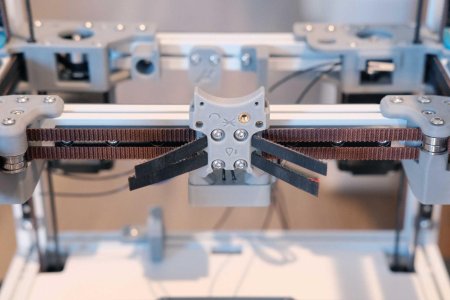

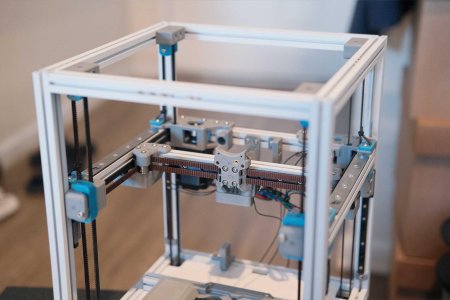

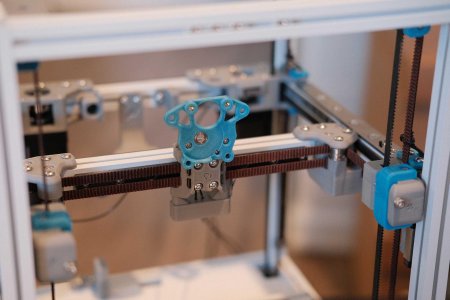

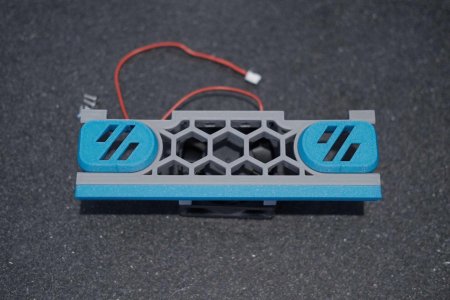

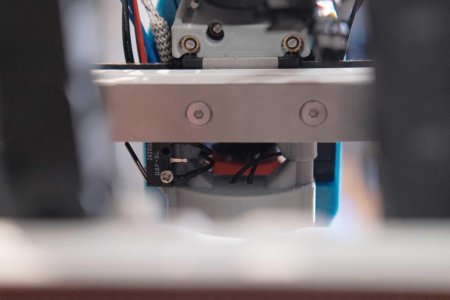

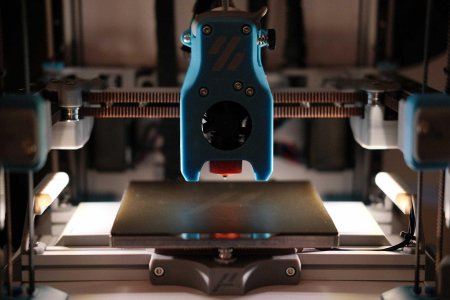

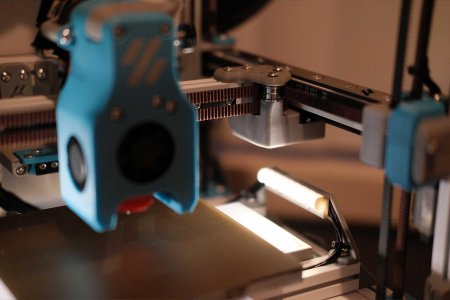

The belt clamps have a recess to accept the belt. That should face downwards. The belt tensioners should have the heads of their SHCS on top.

The belt clamps have a recess to accept the belt. That should face downwards. The belt tensioners should have the heads of their SHCS on top.