Interesting. Got an pics of how you supported this?

I cannot do photos because I am nowhere near that printer. But I have my 3d designs.

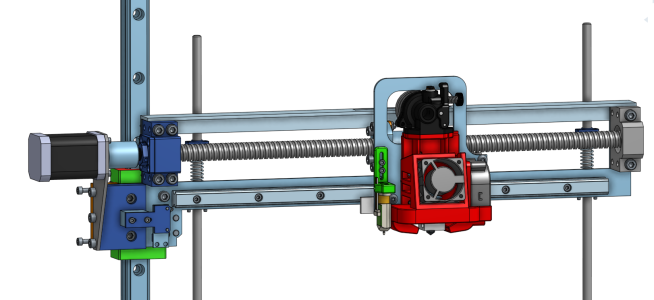

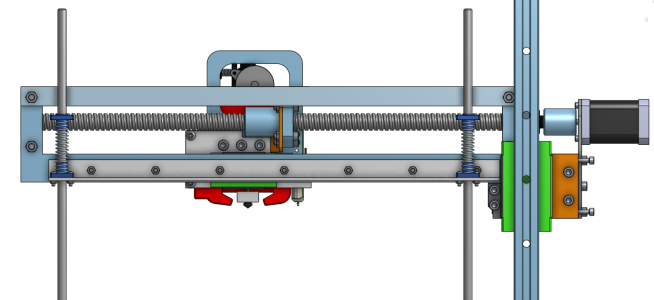

In the front view you can see the frame for both the rail and the ball screw. That frame is only 3 mm thin so it does bear a little bit of the load but the rails does the bulk of it. On the left the single Z pillar which is a Hiwin 25. The two Z axis trapezium threads are not bearing any load other then the weight.

On the rear view you can see the plate that mounts it to the Z carriage with the tramming mechanism. The two screws on the right are for adjusting bedlevel parallelity in X and the block at the left is the locker.

The reason for building this is to see what I can get if I follow the principles of a milling machine instead of the light weight frames from the 3d printing world.

In the 3d printing world we have flex and vibrations from the frame and elasticity from those belts everywhere. We solve this by light weight and then software trickery.

In milling machines and cnc machine centers, we have the same problems but the forces are much higher. Here we solve it with stability, rigidity and weight low down. Never with a frame around the whole thing and never with software.

This frankenstein of a machine is not yet finished and it will be slow in the beginning. I have two nema 23 steppers available for those ballscrews (Y axis is also with a ballscrew), but with a pitch of 5 mm per rev it might not be fast enough.

One thing is for sure though, with 65 kg nearly at bed level it will be accurate.

If it works, and that is a big if, I might try rebuilding it later with servos for X and Y. I still don't know if the small nema 17 are strong enough to lift all the weight but I reserved some whopping 56 mm motors for it so we will see, there is a chance it will work.

since the X and the Y are split in bedslingers, you will not need to build rigidity for the Y direction in the X axis, because it does not translate to there. The beefy foot plate with those solid feet will easilly absorb any vibration from the bed so the X will hardly see any of that.

At leats that is the theory.

If this thing works I will use it for difficult materials that need hardened nozzles and I will put in in some enclosure with temp control.

This is future music however. As of now it is still only half built and although I have all the parts, my mind is as restless as a kitten on a caffeine shot, so I keep giving myself other projects to unfinnish.