Hi, it's better to use links to creator's GitHub repository directly, to give them credit

Bed Fans

Macros and Usage See bedfans.cfg or bedfans-dualcontrol.cfg* for klipper macros. 1) Place the .cfg file in the same directory as your printer.cfg file. 2) Add [include bedfans.cfg] to your printer.cfg. 3) Change pin for your fans in the second section. This is intentionally left blank so that it ...www.teamfdm.com

VORON Design

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question Day 0 V2.4 Mods

- Thread starter ZombieHedgehog

- Start date

dunar

Member

Small QOL change I do on most of my printers: additional temperature sensors.

Chamber temperature sensor to know when the printer is up to temp

Second temperature sensor attached to the corner of the build plate (either using a M3 screw in thermistor in a tapped hole or a embedded in a blind bore secured with a set screw depending on how i felt when building the thing)

Chamber temperature sensor to know when the printer is up to temp

Second temperature sensor attached to the corner of the build plate (either using a M3 screw in thermistor in a tapped hole or a embedded in a blind bore secured with a set screw depending on how i felt when building the thing)

ill have to try the thin version!

ZombieHedgehog

New member

I know the mod is old and abandoned but https://github.com/VoronDesign/Voro...Decontaminator_Purge_Bucket_&_Nozzle_Scrubber is amazing, not so much for the bucket nor the scrubber (although they are useful!) but for the stoppers at the edge of the bed, because it realigns the steel plate instantly at the proper distance all the time.

Personally I stuck with the legacy Revision #2 and it's been perfect, I will always rebuild my V2 with that mod.

Great idea to add the plate stopper! I do have one of those nozzle brushes and might add that too in the future.

You mention both Orbiter 2.0 and 2 part toolhead PCB, but there is no way to use those together afaik. The Orbiter's tension latch would interfere.

Good catch, I was originally planning on using CW2 so I have the parts for it. I'm currently using the orbiter on another build and the quality is very good at the moment so I can keep it on there for now.

These both look great, this is something I would want to install with the build so I'll look into them!

The Voron 2.4 Filament Latch just came out with a slim print in place version that feels much more durable.

The same repo has a set of handles for the lower back corner and I wish I would have printed them sooner. The build is large and can be quite awkward to move around once everything is attached you can kinda pick it up by the feet/skirt but it does not spark joy the same way the handles do.

GitHub - v6cl/My-Voron2.4-Customs: My Voron2.4 Customs

My Voron2.4 Customs. Contribute to v6cl/My-Voron2.4-Customs development by creating an account on GitHub.github.com

Handles seem handy when the panels are installed. I'll look at the print in place version too and see which one I like more

Corrected, and thanks for alerting that it wouldn't be compatible with my build!

Hi, it's better to use links to creator's GitHub repository directly, to give them credithttps://github.com/VoronDesign/VoronUsers/tree/master/printer_mods/Ellis/Bed_Fans

Thanks for the link, I was originally sent the link and had it saved on printables. I'll make sure all the links/information are accurate during the build series

Small QOL change I do on most of my printers: additional temperature sensors.

Chamber temperature sensor to know when the printer is up to temp

Second temperature sensor attached to the corner of the build plate (either using a M3 screw in thermistor in a tapped hole or a embedded in a blind bore secured with a set screw depending on how i felt when building the thing)

Thats a great idea too, I'll look around for different parts or make my own

Yezariael

Well-known member

geekandi

Member

This things are awesome; if you want a vote of confidence then here you go!I was recommended to use these panel clips: https://www.printables.com/model/172368-voron-24-filament-latch-or-any-2020-extrusion

5twenty

Well-known member

I love that mod, however I had to redesign the brush holder to bring the brush up higher. And then there is the lack of good brushes out there. I just ordered a pack of "copper" brushes that surprisingly love my magnets. So, I guess I'll pass on those obvious steel brushes. The brass ones that I have are too sparse for the brush to clean efficiently. But the cheap brushes that come with almost all 3d printers are good for the job.I know the mod is old and abandoned but https://github.com/VoronDesign/Voro...Decontaminator_Purge_Bucket_&_Nozzle_Scrubber is amazing, not so much for the bucket nor the scrubber (although they are useful!) but for the stoppers at the edge of the bed, because it realigns the steel plate instantly at the proper distance all the time.

Personally I stuck with the legacy Revision #2 and it's been perfect, I will always rebuild my V2 with that mod.

I might have to switch my scrubber and bucket to the side so I can zig-zag through the brush.

My advice to OP, and I'm sure I'm not the only one who has said it; make sure to incorporate all the mods that will require disassembly later into the beginning phase to reduce tearing it down too much. Though I am getting ready to start tearing my 2.4 down and rebuilding it. After building a couple it is easier to look back and see what you missed. So build it and build the next one.

PrintStructor

New member

I would definitely go with the times on a new build and directly install the BTT EBB36 can board. With this you save a lot of cables and have the ADXL directly installed. You can also connect the Octopus board directly. I did it the same way with my last build.I plan on using a BTT EBB36 CAN Bus on the toolhead. You only need four wires between MCU and toolhead and this can eliminate the X & Y cable chains. There is also, an ADXL345 built in to it for resonance testing. I don't have any first hand experience with it, but it looks to me like it will clean up the build quite a bit. You might want to look into this before investing in the HartK toolhead PCB. However it would probably better if put printer together "stock" and get it up and running before trying the EBB36.

LeeWright

New member

Im just about to go AB - SB and wondering if I should wait or if I should go ahead and retro fit tap.Don't use Klicky, wait for the New TapTapTap.

Yezariael

Well-known member

I don't like the idea that there are moving parts in the extruder and that it is bumping into the buildplate... time will tell!Im just about to go AB - SB and wondering if I should wait or if I should go ahead and retro fit tap.

LeeWright

New member

Its a concern but at this point shouldn't we have faith that they have tested a design like this thoroughly before release?I don't like the idea that there are moving parts in the extruder and that it is bumping into the buildplate... time will tell!

ZombieHedgehog

New member

My advice to OP, and I'm sure I'm not the only one who has said it; make sure to incorporate all the mods that will require disassembly later into the beginning phase to reduce tearing it down too much. Though I am getting ready to start tearing my 2.4 down and rebuilding it. After building a couple it is easier to look back and see what you missed. So build it and build the next one.

This is exactly what I'm trying to do, figure out all the random mods that I don't know about BEFORE I build/print everything. All suggestions are very welcome

Technoplunk

New member

I keep meaning to move mine to the front or a side. It's definitely a pain reaching all the way around to the back. The bigger the printer the worse it gets.The only mod that I have done to the Voron 2.x that I feel is better then standard Voron build is add a power switch to the front of the machine.

cross2010

New member

I would HIGHLY recommend looking into using canBUS on the print head. This eliminates a lot of wires and makes things a bit cleaner on the inside of the printer. The process seems daunting but there are a lot of good guides that have recently shown up that are a huge help. I personally have my V2 and Switchwire set up with the BTT USB2Can adapter and the EBB36 canBoard.

I ended up switching to this because I have gone through a couple of wire looms due to wires breaking in the drag chains.

I ended up switching to this because I have gone through a couple of wire looms due to wires breaking in the drag chains.

What mods to include in the initial build is a great question because you don’t want to have to tear down what you just built.

Here are a few I found to include in my initial build:

• Roller Brackets: Super useful for accessing the electronics bay during and after the build.

• V2.4 Handles: Sturdy and good looking handles.

• BTT PITFT50 45-degree Mount: I found and tried a 5" LCD mount that pivoted so you could adjust the angle. But it turned out that it blocked the smooth opening of the doors. So I switched to this one. You may want to install the simpler, non-TFT, non-graphical screen first to make sure everything works. But I found it easy enough to get the touchscreen working.

• Nozzle Scrubber with a Little Bucket for Voron 2.4: I really liked the "Decontaminator" brush/bucket, especially the idea of having alignment screws to quickly set the steel plate correctly. However, 1) the brush was too low, and 2) the 10x2mm pins barely screwed into the soft plastic and appeared way too flimsy to withstand the steel plate knocking into them. So I went with this simpler scrubber/bucket. I would like to see someone design a good plate aligner, but I'm guessing it can't be just printed plastic because it has to touch or come very close to the heated bed where it could melt.

• Voron V2.4 Skirt Buttons Mod: I considered these because they seem like a great idea, especially the idea of having a physical emergency stop button. Ultimately, though, I didn't install these figuring I would wait to see which buttons I actually wanted. Turns out I haven't really needed any. The touchscreen works well.

The general recommendation of the community is to build the canonical Voron 2.4, and then, only after it's working, take on more advanced mods. I think that's good advice for something as complex as CANBUS, which when I last looked lacked extensive documentation and a lot of community experience. However, I did build the Clockwork2 and Stealthburner directly instead of starting with CW1/Afterburner as shown in the official build guide. Having some challenge was part of the fun!

Here are a few I found to include in my initial build:

• Roller Brackets: Super useful for accessing the electronics bay during and after the build.

• V2.4 Handles: Sturdy and good looking handles.

• BTT PITFT50 45-degree Mount: I found and tried a 5" LCD mount that pivoted so you could adjust the angle. But it turned out that it blocked the smooth opening of the doors. So I switched to this one. You may want to install the simpler, non-TFT, non-graphical screen first to make sure everything works. But I found it easy enough to get the touchscreen working.

• Nozzle Scrubber with a Little Bucket for Voron 2.4: I really liked the "Decontaminator" brush/bucket, especially the idea of having alignment screws to quickly set the steel plate correctly. However, 1) the brush was too low, and 2) the 10x2mm pins barely screwed into the soft plastic and appeared way too flimsy to withstand the steel plate knocking into them. So I went with this simpler scrubber/bucket. I would like to see someone design a good plate aligner, but I'm guessing it can't be just printed plastic because it has to touch or come very close to the heated bed where it could melt.

• Voron V2.4 Skirt Buttons Mod: I considered these because they seem like a great idea, especially the idea of having a physical emergency stop button. Ultimately, though, I didn't install these figuring I would wait to see which buttons I actually wanted. Turns out I haven't really needed any. The touchscreen works well.

The general recommendation of the community is to build the canonical Voron 2.4, and then, only after it's working, take on more advanced mods. I think that's good advice for something as complex as CANBUS, which when I last looked lacked extensive documentation and a lot of community experience. However, I did build the Clockwork2 and Stealthburner directly instead of starting with CW1/Afterburner as shown in the official build guide. Having some challenge was part of the fun!

Cr4zyfool

New member

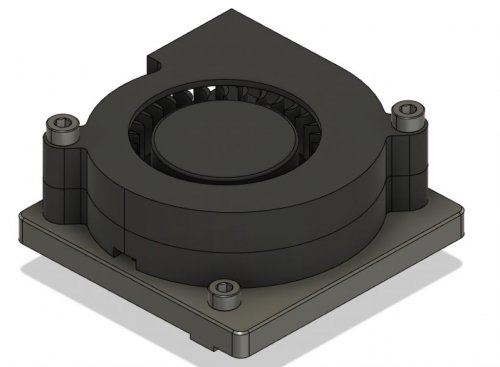

I like this mod for the nozzle brush as well as holds wago clips for your connections to the heater pad etc.

github.com

github.com

GitHub - Midnite3DP/voron-bedpan: A central purge bucket, wago mount, and cover plate for the Voron 2.4

A central purge bucket, wago mount, and cover plate for the Voron 2.4 - GitHub - Midnite3DP/voron-bedpan: A central purge bucket, wago mount, and cover plate for the Voron 2.4

Driden - LSLabs.co.uk

Member

My got to list is now

GE5C Mod

Ramalama Idlers

Pin Mod

Purge Bucket

Unklicky

270 degree removable front doors

magnetic fixed side panels

Nevermore

and i used to really like the decontaminator purge bucket up until i just saw the bedpan in the post above.

GE5C Mod

Ramalama Idlers

Pin Mod

Purge Bucket

Unklicky

270 degree removable front doors

magnetic fixed side panels

Nevermore

and i used to really like the decontaminator purge bucket up until i just saw the bedpan in the post above.

Slewfoot

Member

If you are planning on installing case lights, I would recommend printing and installing these...

5v LED Strip

LED Strip Holder

It's pretty simple to wire them in. just grab power from your 5v supply and find a spare data pin for the signal line.

I just finished doing a complete re-wire and printed these out for installation while I had the printer apart. Super happy with the result. It was also something that I would have done while building the thing if I had thought about it. I've got a simple Caselight On toggle button that I added to klipper screen that just executes this macro.

and the Macro itself...

5v LED Strip

LED Strip Holder

It's pretty simple to wire them in. just grab power from your 5v supply and find a spare data pin for the signal line.

I just finished doing a complete re-wire and printed these out for installation while I had the printer apart. Super happy with the result. It was also something that I would have done while building the thing if I had thought about it. I've got a simple Caselight On toggle button that I added to klipper screen that just executes this macro.

[neopixel caselight]

pin: z:P1.24

# The pin connected to the neopixel. This parameter must be

# provided.

chain_count: 84

# The number of Neopixel chips that are "daisy chained" to the

# provided pin. The default is 1 (which indicates only a single

# Neopixel is connected to the pin).

color_order: GRB

# Set the pixel order required by the LED hardware. Options are GRB,

# RGB, GRBW, or RGBW. The default is GRB.

initial_RED: 1.0

initial_GREEN: 1.0

initial_BLUE: 1.0

and the Macro itself...

[gcode_macro caselight_on]

variable_light_state: 0

gcode:

{% if printer[ "gcode_macro caselight_on" ].light_state == 0 %}

SET_GCODE_VARIABLE MACRO=caselight_on VARIABLE=light_state VALUE=1

SET_LED LED=caselight RED=1 GREEN=1 BLUE=1

{% else %}

SET_GCODE_VARIABLE MACRO=caselight_on VARIABLE=light_state VALUE=0

SET_LED LED=caselight RED=0 GREEN=0 BLUE=0

{% endif %}

Similar threads

- Replies

- 26

- Views

- 2K

- Replies

- 1

- Views

- 857