MichaelOToole

Well-known member

I have started to play with macros but that's for later, first I need to fix a few issues...

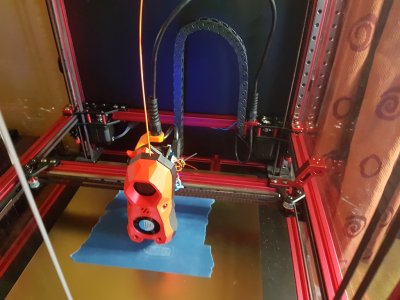

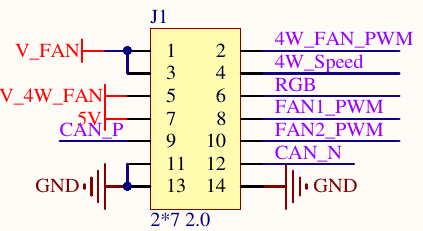

1: Stealthburner LEDs not working: Wrong pin or electrical problem.

2: No filament extruded for one to three seconds at start of prints: Adding a purge line might help?

3: Too many prints coming loose at the start and during a print: Do I have the Z offset wrong?

4: Have to set txqueuelen manually (its not being read from can0 file)... (may have found a fix for this, testing... yes the fix works!)

1: Stealthburner LEDs not working: Wrong pin or electrical problem.

2: No filament extruded for one to three seconds at start of prints: Adding a purge line might help?

3: Too many prints coming loose at the start and during a print: Do I have the Z offset wrong?

4: Have to set txqueuelen manually (its not being read from can0 file)... (may have found a fix for this, testing... yes the fix works!)

Last edited: