Hello, there are few things which you should check at the hardware level:

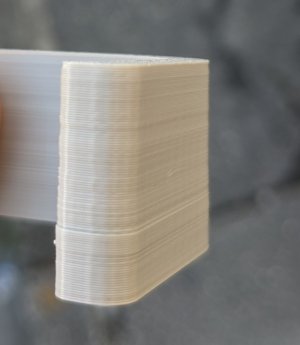

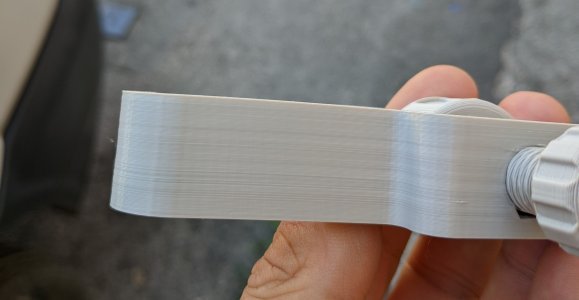

1. Are linear rails running smooth? Did you clean and lubricate them before putting them on?

2. Is your gantry de-racked, both with and without belts?

3. Are belts the same length? When you install XY belts,install one belt, shorten to necessary length (few teeth poking out of X carriage, do not cut flush), pull it out, attach to another belt face to face for teeth to mesh, and cut the the exact same length by teeth. then install both belts and make sure same number of teeth poke out from X carriage. Tension belts to approx 110-115 Hz over 150 mm of belt length.

4. Are belts running on pulleys and bearing stacks? Are they not riding on flanges at any phase of movement? Move toolhead around and carefully observe each and every bearing stack, idler and pulley.

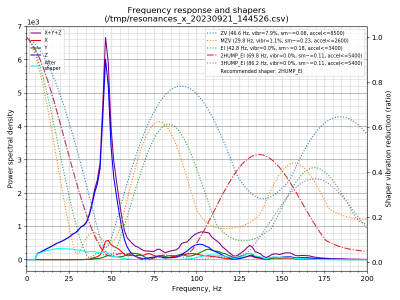

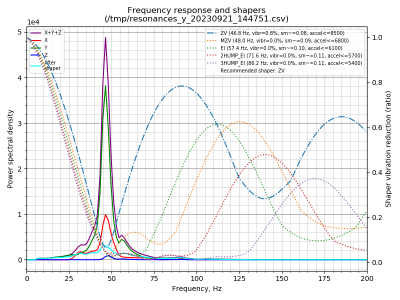

5. You have Tap. Is it properly installed, screwed in tightly, are magnets on sides aligned with FHCS screws? No side wobble? How do your ADXL graphs look like?

6. Are all 4 Z belts tightened the same? Are Z modules assembled properly? No binding when moving gantry up or down?

7. When you have panels installed, did you use foam strips? Else those Z belt ends rub on plexi and prevent movement in Z.

8. What current are you rinning for AB motors? WHat motors are those? What's their max current they support? Are you cooling your TMC drivers?

9. Is extruder assembled properly? Is anti-squish and idler tightened properly? Watch these videos on how to properly adjust your extruder:

https://www.youtube.com/@dr.davesworkshop3585/videos