References

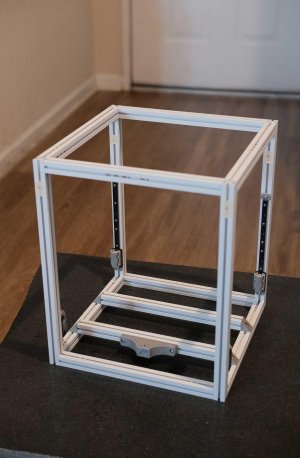

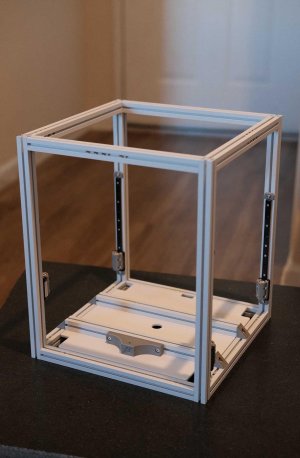

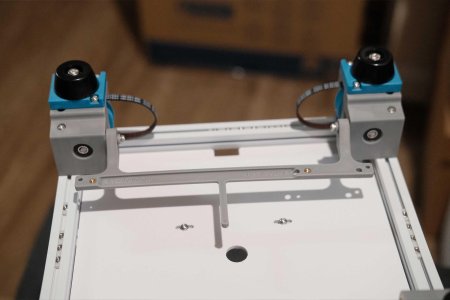

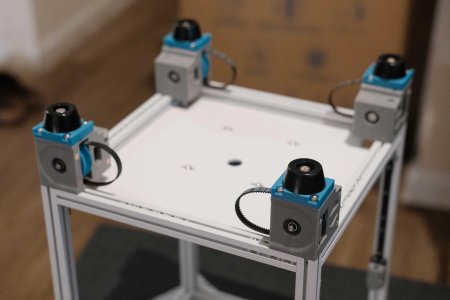

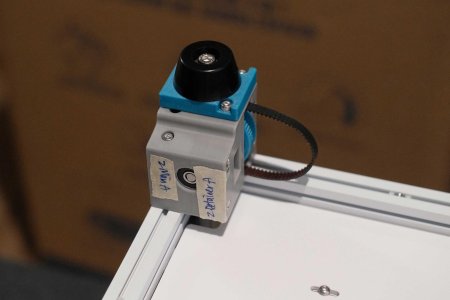

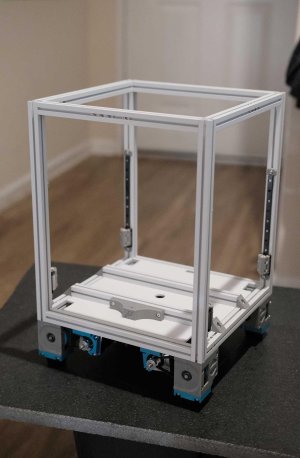

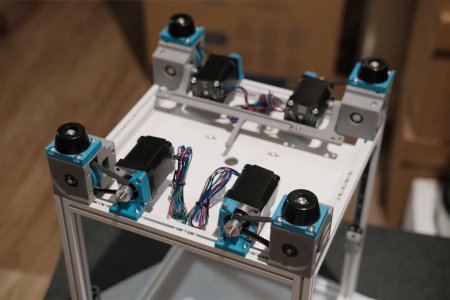

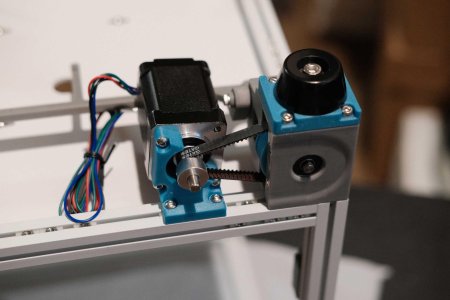

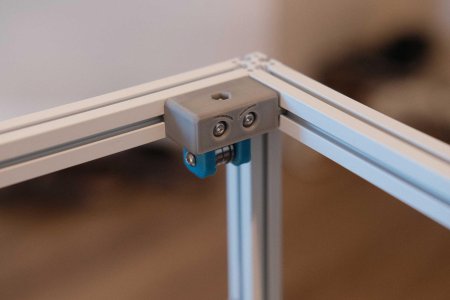

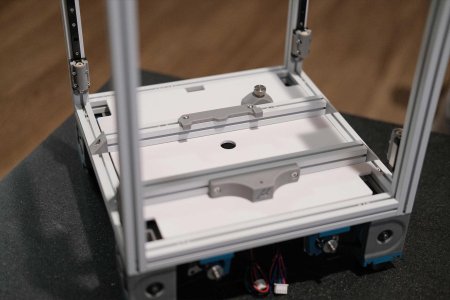

- GitHub - PrintersForAnts/Micron

- Kit - DFH Powder-coated White Micron

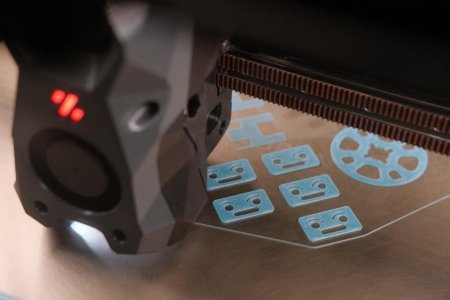

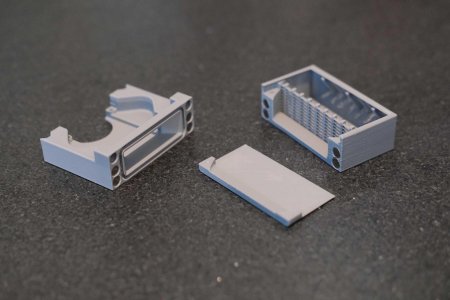

- Filament 1 - Fusion Filament’s Electrolytic Deuterium

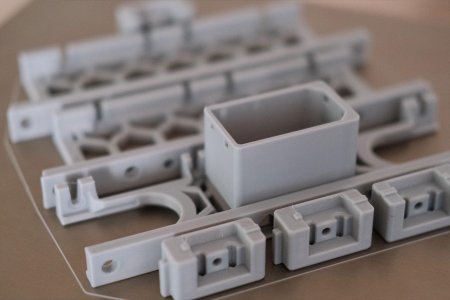

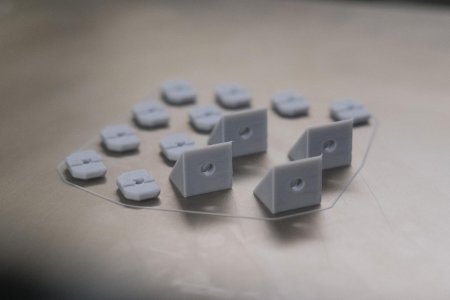

- Filament 2 - Fusion Filament’s Mushroom Cloud Grey

- Octopus - Pinout, v2.4 Wiring Guide, 3DWork Guide

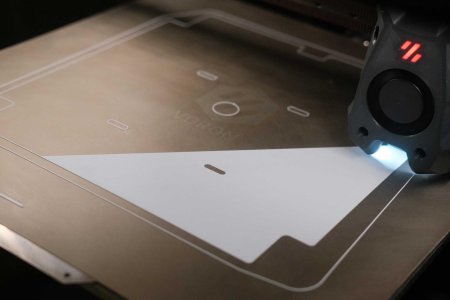

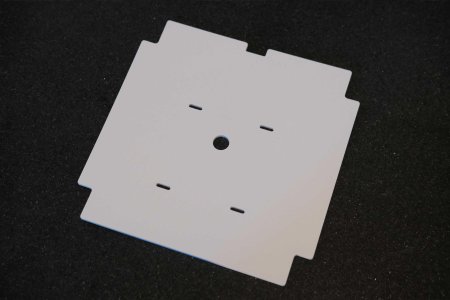

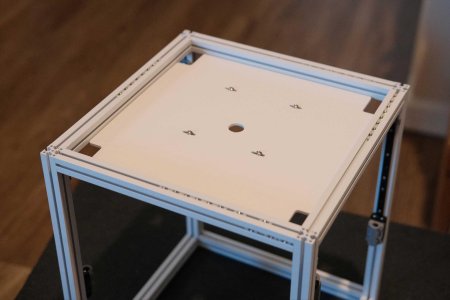

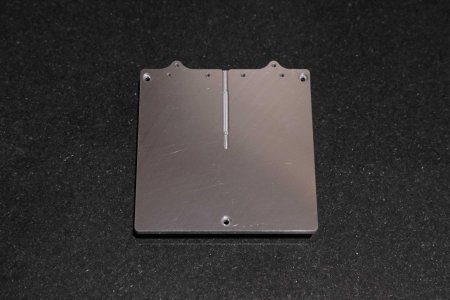

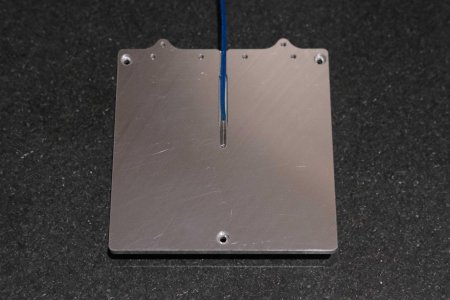

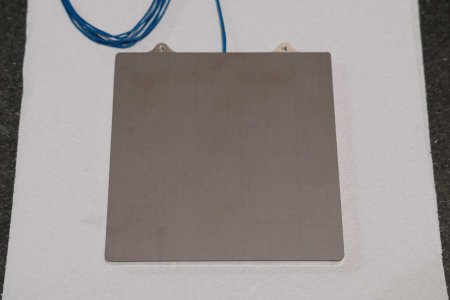

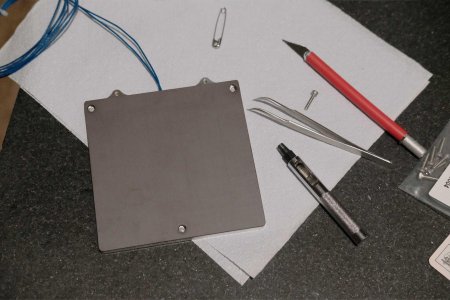

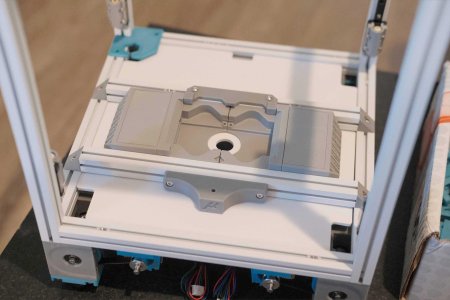

- Aluminum Bed - PrecisePrinterParts v0 Bed

- Stainless Steel Fasteners - West3D BDF Fasteners Kit for Mcron

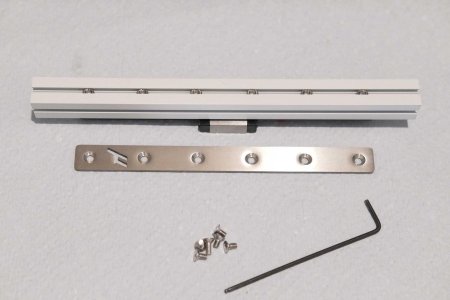

- Titanium Backers - DFH

- Titanium Nut Bars - DFH

- Blue Manganese Flex Plate - DFH

Attachments

Last edited: